Civil Engineering Reference

In-Depth Information

Sputter deposition

Sputter cathode

Vacuum chamber

Unheated glass

Sputter plasma

(a)

Spray pyrolysis

Spray nozzle

Aerosol

(b)

Heated glass

8.15

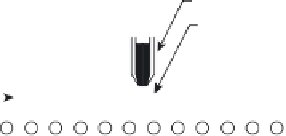

Principles for sputter deposition (a) and for spray pyrolysis

(b) to coat surfaces of glass transported as indicated by the horizontal

arrows. From Granqvist (1991).

of sheet glass in order to make thin fi lms that can give low thermal emission

and thereby good thermal insulation in a double-glazed window, or thin

fi lms that control the throughput of solar energy so that the need for air

conditioning is diminished. Figure 8.15 shows two principles of how this is

done (Granqvist, 1991): panel (a) illustrates sputtering onto moving sheet

glass in a continuous process wherein panes are entering though a load lock

at one end of a deposition unit and exiting at the other end, and panel (b)

demonstrates another technique based on spray deposition of a metal-

containing solution onto hot glass, most conveniently as the sheet glass

emerges from the leer during fl oat glass production. More detailed discus-

sions of glass coating are given elsewhere, in particular in topics and papers

by Gläser (2000, 2008) and by Bach and Krause (2003). The practical depo-

sition systems - particularly for sputter deposition - can be very large and

involve a multitude of sputter targets mounted along a production line that

is more than 100 m in length; Fig. 8.16 is a photograph of a system of this

kind.

'Web coating' of fl exible substrates (Schiller

et al.

, 2000; Fahlteich

et al.

,

2012) is a well-developed technology with possibilities for excellent process

control. It can be used to make thin fi lms cost-effectively on very large

Search WWH ::

Custom Search