Civil Engineering Reference

In-Depth Information

binder, a polymer coating solution, or a monomer solution prior to polym-

erization. The latter process can be used to produce master batches of

concentrated nanoparticles in resin, which can subsequently be mixed with

clear resin to prepare thin polymer foils doped with nanoparticles by extru-

sion. These foils can then be stuck onto surfaces or positioned between clear

sheets. Nanoparticle-doped polymer sheets and other shapes of plastic can

also be made by injection moulding and extrusion from suitable resins. If

dilute coatings are needed, it is important to make sure that the particles

are dispersed, which usually requires a surfactant (i.e., a 'soap' type mole-

cule) on their surface to ensure that they do not stick together.

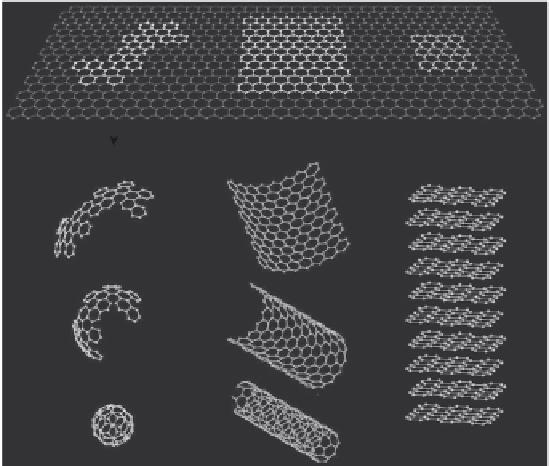

Carbon-based nanomaterials deserve particular attention and have

undergone phenomenal development during recent years. Figure 8.13 illus-

trates how different nanostructures can be created from a two-dimensional

arrangement of carbon atoms to yield C

60

units (known as 'buckminster-

fullerene molecules' or 'buckyballs'), long nanotubes with metallic and

semiconducting properties, and graphene (two-dimensional graphite-like

sheaths) (Geim and Novoselov, 2007).

Long nanoparticles can be prepared not only from carbon, as indicated

in Fig. 8.13, but from many materials. Figure 8.14 illustrates an example

of Ag nanowires that can be made from potentially inexpensive reduction

of liquid silver nitrate to make electrically conducting and transparent

8.13

Schematic rendition of carbon-based nanostructures and of their

formation. From Geim and Novoselov (2007).

Search WWH ::

Custom Search