Civil Engineering Reference

In-Depth Information

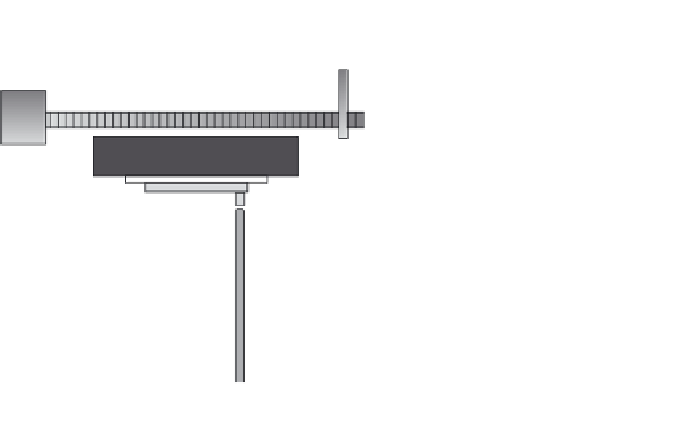

Vacuum pump

Deposition

chamber

Substrate

Nozzle

Film

Transfer pipe

Evaporation pipe

Evaporation

chamber

Tungsten oxidation

Induction heating

generator

Tungsten pellet

Pedestal

Synthetic air

8.11

Schematic image of a unit for advanced gas deposition arranged

for making tungsten oxide nanoparticles. From Reyes

et al.

(2004).

now used to mass-produce nanoparticles that can be collected for later use

or for coating directly onto substrates. The technique and its implementa-

tion are described in detail in a topic by Hayashi

et al.

(1997).

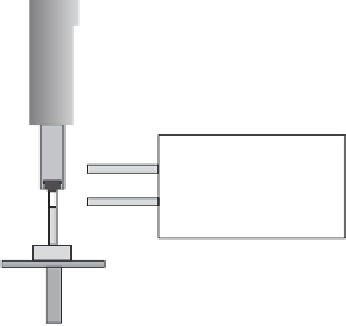

Figure 8.11 illustrates an AGD unit; as shown, it is arranged for tungsten

oxide nanoparticle production (Reyes

et al.

, 2004) but the technique can be

used reactively or non-reactively to make nanoparticles of a large variety

of pure metals, oxides, nitrides, etc. Evaporation takes place in the lower

chamber into a laminar gas fl ow surrounding the vapour source. The vapor-

ized species are then cooled via collisions with gas molecules so that they

form tiny nuclei that subsequently grow in the gas fl ow. A thin transfer pipe

collects nanoparticles in a region at a controlled distance from the vapour

source and transports them in a gas stream that ends in the upper deposi-

tion chamber, which is maintained at good vacuum. A separate evacuation

Search WWH ::

Custom Search