Civil Engineering Reference

In-Depth Information

120

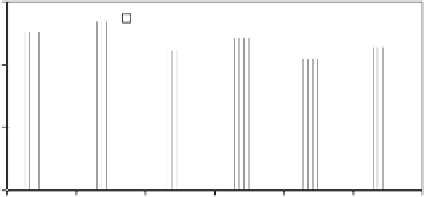

Nanofill-15, 7%

Cloisite-15A, 7%

80

40

0

750

900

1100

1300

1500

1800

Stress level (kPa)

6.16

Percent life increase and stress levels at 5°C.

300

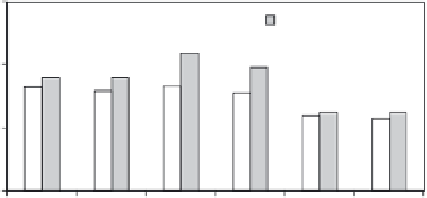

Nanofill-15, 7%

Cloisite-15A, 7%

200

100

0

150

200

250

300

350

400

Stress level (kPa)

6.17

Percent life increase and stress levels at 25°C.

6.6 Conclusion

When bitumen is modifi ed with small amounts of nanoclay, its physical

properties are successfully enhanced on the condition that the clay is dis-

persed at nanoscopic level. Nanoclay materials have a larger aspect ratio

and large surface area, and their particles are not uniform in size and

arrangement. Nanofi ll-15 particles are smaller in size as compared to the

Cloisite-15A particles. The plastic limit shows that nanoclay materials are

the expansive type of clay. Adding low percentages of nanoclay to bitumen

changes rheological properties, decreases penetration and ductility, and

increases softening point and ageing. Tests performed on binders and dense

asphalt mixtures show that the Cloisite-15A and Nanofi ll-15 modifi cations

increase the stiffness and improve the rutting resistance, indirect tensile

strength, resilient modulus and Marshall stability. However, fatigue perfor-

mance decreases at low temperatures. Also optimum bitumen and VTM

increase a little by adding nanoclay.

Search WWH ::

Custom Search