Civil Engineering Reference

In-Depth Information

80

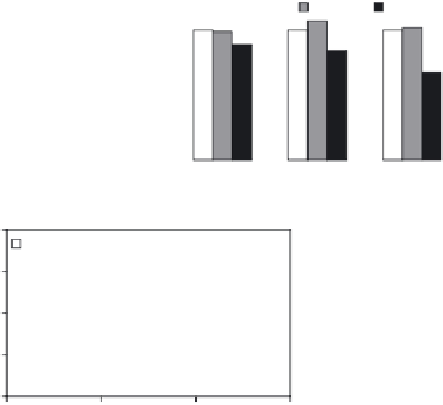

Unmodiied binder

Nanoill-15

Cloisite-15A

60

40

20

0

2%

4%

7%

Nanoclay content

65

150

Unmodiied binder

Nanoill-15

Cloisite-15A

Unmodiied binder

Nanoill-15

Cloisite-15A

120

60

90

60

55

50

30

0

45

2%

4%

7%

2%

4%

7%

Nanoclay content

Nanoclay content

6.4

Rheological results test and nanoclay content.

Cloisite-15A content caused a decrease in penetration. Nanofi ll-15 has little

effect on softening point; by adding 7% nanofi ll, softening point increased

by only 3%. In contrast, Cloisite-15A has a relatively higher impact on

penetration and softening point of bitumen. By increasing Cloisite-15A

content, penetration decreases from 63 to 45 and softening point increases

from 54 to 61. Also both nanoclays reduce ductility of binder but Cloisite-

15A has a more pronounced effect in reducing ductility. This behaviour may

be the result of chemical reaction and change in chemical structure, as

pointed out by Ghile (2005).

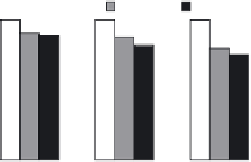

When bitumen gets aged it becomes harder. Retained penetration (RP)

and increase in softening point (ISP) values, as defi ned below, were used to

fi nd the ageing effect:

aged penetration

unaged penetration

()

=

RP

%

×

100

°

()

=

(

)

ISP

C

aged soft

ennig point

−

unaged softening point

[6.2]

A lower RP value and higher ISP refl ect more ageing of the binder. Long-

term ageing was performed for 20 hours at 90°C and atmospheric pressure.

The retained penetration and increase in softening point were computed

and are presented in Fig. 6.5. It can be observed that there are some

improvements in the resistance to ageing in the long term due to the

Nanofi ll-15 modifi cation and therefore it will probably suffer less when in

contact with hot air or hot oxygen.

Search WWH ::

Custom Search