Civil Engineering Reference

In-Depth Information

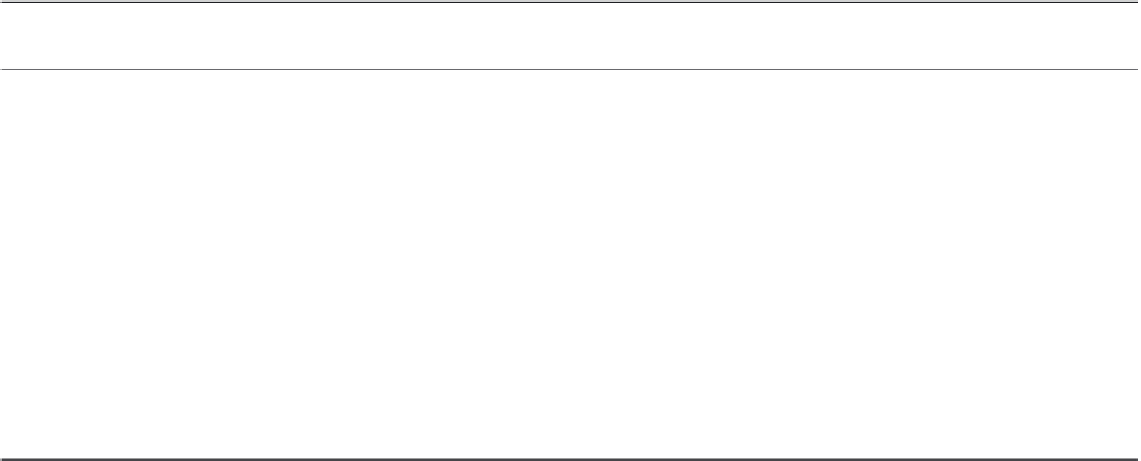

Table 5.3

Recent research on the utilization of nanotechnology to improve the corrosion resistance of steel

Production

process

Microstructure

of

surface

or

bulk

Novel

properties

or

phenomenon

Reference

Steel

type

Mechanism(s)

Zhang

et al.

(2001)

Tool steel

(0.35C-5Cr-

1.5Mo-1V)

Metal vapor

vacuum arc

ion

implantation

Fe

2

Mo, FeMo, Fe

2

MoC,

Mo

2

C, MoC, MoC

x

nano-precipitates in

surface layer

Greatly improved

resistance to pitting

corrosion and

corrosion

Nano-(Mo

+

C) phases

improve the passive

fi lm

Wang and

Li (2003)

304 SS

Sandblasting

+

annealing

Uniformly distributed

nanocrystalline

grains (

∼

20 nm) in

the top surface

Greatly improved

resistance to

corrosion, wear and

corrosive wear

Nanocrystallization and

change in the

dominant wear

mechanics

Kwok

et al.

(2006)

316 SS

Cavitation

+

low-

temperature

annealing

fcc

γ

-grains (91 nm)

Improved resistance to

pitting corrosion and

enhanced ability to

repassivate

High density of GBs as

nucleation sites for

growing a uniform

Cr-rich passive fi lm

Vaynman

et al.

(2002)

NUCu weathering

steel (ASTM

A710B, 0.06% C)

Microalloying

+

hot-rolling

+

normalizing

Equaxed ferritic

microstructure,

with some dispersed

pearlite bands

Outstanding

mechanical, welding

and anti-corrosion

properties, e.g., TS of

567 MPa, El of 32.2%

Hardening by nano-Cu

precipitation; solid

solution strengthening

by Ni; grain

refi nement by Nb

Search WWH ::

Custom Search