Civil Engineering Reference

In-Depth Information

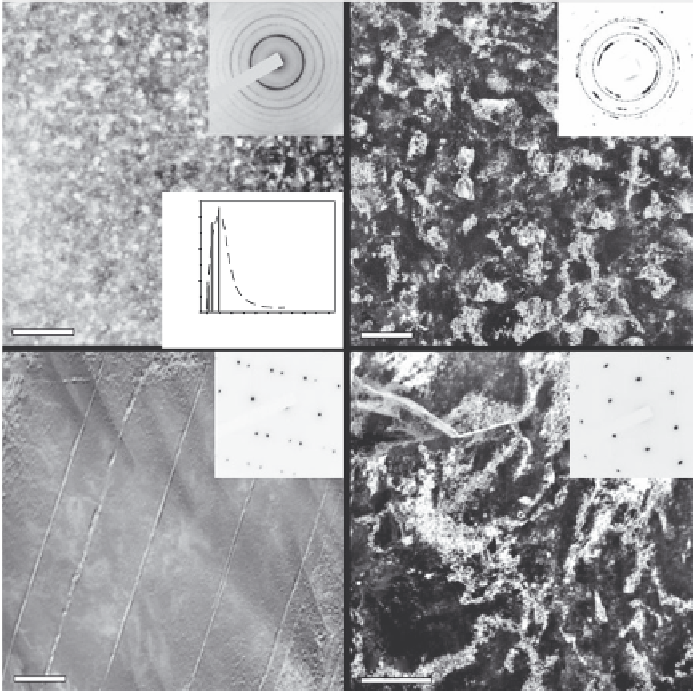

ultrafi ne layer, twinning layer, and compliant

coarse-grained layer from outer to inner of the stainless steel. This bio-

inspired design aims to benefi t from the synergy of multiple deformation

mechanisms and nano/micro-scale toughening. Figure 5.4 presents typical

TEM images of 304 SS after SMAT and its corresponding selected area

electron diffraction (SAED) patterns at four different depths (Chen

et al.

,

2011).

Another advance in this fi eld deals with the use of surface-modifi ed

nano-Cu as effective lubrication additive (at 10 vol% in oil). It works by

'forming a chemical reaction fi lm on the steel' surfaces, thus improving their

nanocrystalline

α

′

layer,

α

′

-

γ

g

a′

30

d = 10 nm

20

10

(a)

(b)

100 nm

0

200 nm

0

20 40 60 80 100

Grain size (nm)

(c)

(d)

500 nm

5

5

5

μ

μ

μ

m

m

m

5.4

Typical TEM images of 304 SS after SMAT and its corresponding

selected area electron diffraction (SAED) patterns at four different

depths: 5, 100, 250, and 400

m for (a)-(d) respectively. The lower

inset of (a) is the grain size distribution (Chen

et al.

, 2011).

With

kind

permission

from

Elsevier

Science.

μ

Search WWH ::

Custom Search