Environmental Engineering Reference

In-Depth Information

•

Environmental Compatibility.

Environmentally compatible by-products.

•

Construction Method.

Easy construction, that is, minimization of

excavated material.

Common contaminants (e.g., trichloroethylene) and common reactive

media (e.g., granular ZVI) are the most common PRBs applications used to

date (Thiruvenkatachari et al. 2008; Gavaskar et al. 2000; RTDF 2001). Whereas

the technology initially used ZVI as the reactive medium for the remediation

of GW contaminated with CHC (with the first field trials in the early 1990s

and the first commercial deployment in late 1994), recently a range of materi-

als for the remediation of other organics have been deployed (Naidu 2013).

For other materials used in PRB see Chapter 1. The use of granular iron PRB

for treating dissolved CHC is rapidly gaining acceptance as a cost-effective

technology due to it being a long-term and low-maintenance cost solution

(O'Hannesin and Gillham 1998; Henderson and Demond 2007).

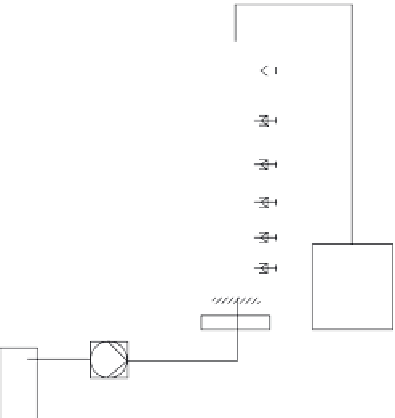

Following site characterization and identification of prospective reactive

media, treatability testing is conducted to evaluate the performance of the

reactive medium with GW from a specific site (see Figure 3.1). Batch tests

can be conducted to initially screen prospective media, but column tests

as illustrated in Figure 3.1 should also be performed (Gavaskar et al. 2000).

Treatability testing serves the following purposes:

• Screening and selecting a suitable medium for the reactive cell.

• Estimating the half-life of the degradation reaction.

1. Contaminated groundwater

2. Interval pump

3. PRB material

4. Treated water container

5. Sampling port

6. Glass bidds

3

5

4

6

2

1

FIGURE 3.1

Laboratory column experiment setup for testing PRB reactive material.

Search WWH ::

Custom Search