Environmental Engineering Reference

In-Depth Information

(a)

Natural ground

Permeable reactive material

Estimated capture zone

GW flow direction

(b)

Permeable reactive material

Permeable reactive material

Bentonite

Bentonite

Sheet piling

Sheet piling

Estimated capture zone

Estimated capture zone

GW flow direction

GW flow direction

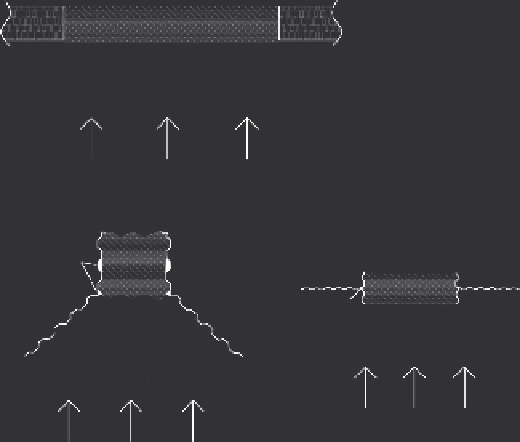

FIGURE 1.4

PRB configuration: (a) continuous barrier and (b) “funnel-and-gate” system.

by large trees, recharge from nearby water body) is a vital step in the design

of a PRB system to ensure that the PRB is oriented perpendicular to the

flow so that it captures the maximum volume of groundwater (Puls, 2006).

Generally, the recommended approach is to conduct high-resolution site

characterization along with groundwater and solute transport modeling to

simulate possible case scenarios and design the orientation and dimensions

of the PRB.

The reactive material used for the construction of the permeable wall var-

ies with the type and concentrations of contaminants, the total mass of con-

taminants, and the groundwater composition (Table 1.2) (Birke et al., 2003;

Thangavadivel et al., 2013). Feasibility studies are crucial for the design of

PRB systems including choice of the reactive material, laboratory column

experiments, estimation of required residence time, and calculation of reac-

tive zone thickness (Roehl et al., 2005a). Since the first PRB trial in Canada

(Gillham and O'Hannesin, 1992, 1994), a range of different contaminant types

have been remediated using reactive materials that vary considerably in

their chemical composition (Table 1.2) and their interactions and mechanism

of contaminant removal. Zero-valent iron (ZVI) is the most common reac-

tive material that generates low redox potential in groundwater, resulting in

the precipitation and removal of both inorganic (metallic) and organic con-

taminants (Meza, 2009; Xenidis et al., 2002). Permeable reactive subsurface

Search WWH ::

Custom Search