Environmental Engineering Reference

In-Depth Information

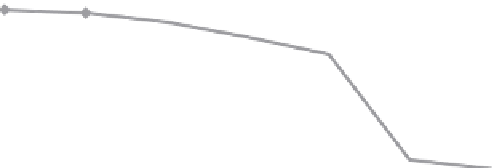

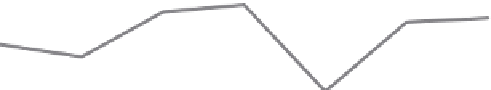

6.8

6.6

6.4

6.2

6.0

5.8

5.6

5.4

5.2

2004

2005

TEPA-1C/D

2006

2007

2008

2009

2010

TEPA-2C/D

TEPA-5C/D

TEPA-6C/D

FIGURE 8.2

Average pH within PRB at four transect locations over time (TEPA-1C/D is through PRB with

wood chips; TEPA-2, TEPA-5, and TEPA-6 are through PRB without wood chips).

The pH at TEPA-1C was as high as 6.40 in 2004 (the year following instal-

lation of the PRB); however, a gradual decline in pH began in 2005 and was

followed by a much sharper decline between 2008 and 2009. The decreas-

ing pH trend at TEPA-1C coincided with increasing aluminum and nickel

concentration trends at this location. The low pH at TEPA-1C also coincided

with the lowest DOC concentration (6.4 mg/L) and highest E

H

(+216 mV)

measured at any location within the PRB in 2010. Despite this apparent early

sign of treatment failure in the upgradient half of the PRB along TEPA-1, a

pH of 6.42 measured at TEPA-1D in 2010 in the downgradient half of the PRB

indicated the PRB still effectively raises the pH of the groundwater prior to

its discharge from the PRB (Figure 8.2).

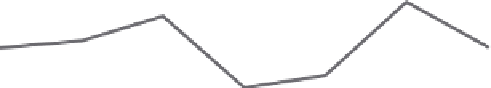

Upon exiting the PRB, pH values remained elevated along all four transects;

however, they decreased with distance from the PRB. The pH values at the

furthermost H wells that were located along the shoulder of the downgradi-

ent creek (see Figure 8.1) ranged from 5.93 at TEPA-2 to 6.18 at TEPA-6 in 2010.

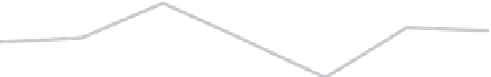

8.1.2.4 Acidity

The removal of acidity (i.e., acid-producing capacity) from the groundwater

is as important a component of the PRB treatment process as raising the pH

of the groundwater, since acidity represents potential acid discharge to the

downgradient creek. Groundwater acidity entering the PRBs was high and

primarily attributable to the presence of dissolved-phase aluminum and fer-

rous iron. Aluminum-based acidity accounted for approximately 80% of the

total mineral acidity entering the PRB and in 2010 ranged from 506 mg/L as

Search WWH ::

Custom Search