Environmental Engineering Reference

In-Depth Information

combined with its location independence, provide a storage technique with unique

characteristics. However, as well as cost, a number of areas need to be investigated

further in this area such as its design, power and storage capacities and environ-

mental impact to prove it is a viable option.

4.3 Compressed air energy storage

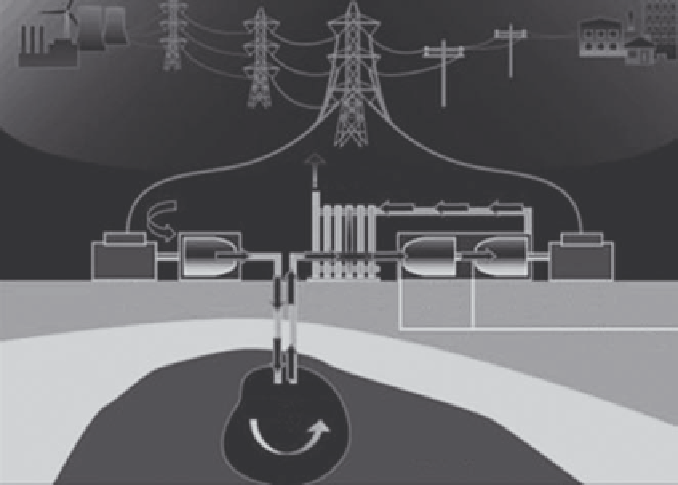

A CAES facility consists of a power train motor that drives a compressor (to com-

press the air into the cavern), high pressure turbine (HPT), a low pressure turbine

(LPT), and a generator (see Fig. 5).

In conventional gas turbines (GTs), 66% of the gas used is required to compress

the air at the time of generation. Therefore, CAES pre-compresses the air using

off-peak electrical power which is taken from the grid to drive a motor (rather than

using gas from the GT plant) and stores it in large storage reservoirs. When the GT

is producing electricity during peak hours, the compressed air is released from the

storage facility and used in the GT cycle. As a result, instead of using expensive

gas to compress the air, cheaper off-peak base-load electricity is used. However,

when the air is released from the cavern it must be mixed with a small amount of

gas before entering the turbine. If there was no gas added, the temperature and

pressure of the air would be problematic. If the pressure using air alone was high

enough to achieve a signifi cant power output, the temperature of the air would be

far too low for the materials and connections to tolerate [1]. The amount of gas

Exhaust

Waste Heat

Air

Recuperator

Compressor

LPT

Generator

Motor

HPT

Fuel (Natural Gas)

Compressed

Air

Salt Dome

Cavern

Figure 5: Compressed air energy storage facility [ 10 ].

Search WWH ::

Custom Search