Environmental Engineering Reference

In-Depth Information

be pitched (rotated around their long axis). Some have rotors that always turn at

a constant or near-constant speed while other designs might change the rotor

speed as the wind changes. Wind turbine rotors may be upwind or downwind of

the tower.

It is worth mentioning that the hub, rotor, and tower may act as loudspeakers,

transmitting the mechanical sound and radiating it. The transmission of noise from

the mechanical parts of a wind turbine can take place in two ways:

structure-borne

air-borne

Structure-borne sound [3] is a sound that is propagated through structures as

vibration and subsequently radiated as sound. The intensity and the frequency of

structure-borne sound depend on many factors such as the rotational speed of the

wind turbine, as well as the type and the material of the mechanical parts that

vibrate. Air-borne [4] means that the sound is directly propagated from the

component surface or interior into the air.

Structure-borne sound is transmitted along other structural components before it

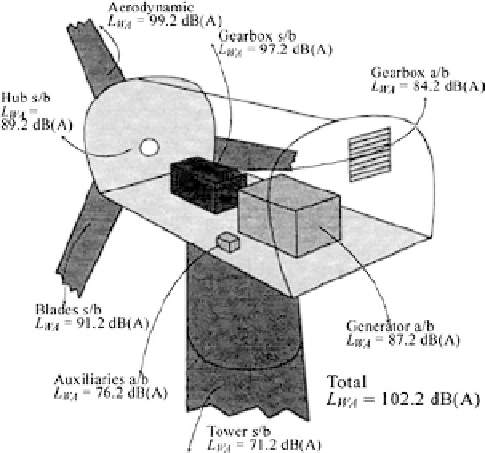

is radiated into the air. For example, Fig. 6 shows the type of transmission path and

the sound power levels for the individual components for a 2 MW wind turbine. Note

that the main source of mechanical sounds in this example is the gearbox, which

radiates sounds from the nacelle surfaces and the machinery enclosure.

Utility scale turbines are usually insulated to prevent mechanical noise from

proliferating outside the nacelle or tower. Small turbines are more likely to produce

noticeable mechanical noise because of insuffi cient insulation.

Figure 6: Sound power levels of wind turbine components [ 1 ].

Search WWH ::

Custom Search