Environmental Engineering Reference

In-Depth Information

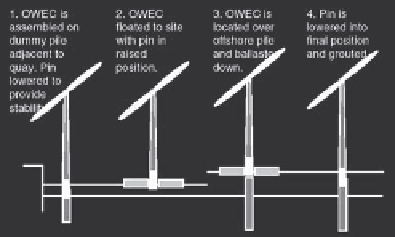

Figure 6: Installation of fully operational turbine and connection details between

foundation pile and tower with misalignment correction.

energy application would require purpose-built vessels because existing vessel

were either too large (offshore cranes) or too small.

2.2 From theory to practice: Horns Rev

The installation of Horns Rev in 2002 was the largest practical test of all theoreti-

cal fi ndings. The installation of the foundation pile was done on a rather traditional

manner: a small jack-up with a crane. For the installation of the turbines however

two ships were entirely converted to purpose-built turbine installation vessels.

Choosing a normal ship would ensure high sailing speed from and to port. A jack-

ing system was added which only pre-stressed the legs without lifting the entire

vessel out of the water. Two blades were already connected to the nacelle before

placing it on the deck of the installation vessel. The method was christened “bunny

ears” for obvious reasons. The installation of the tower and turbine was reduced to

four lifts; two tower sections, nacelle with two blades and the fi nal blade.

All appurtenances were pre-fi tted in port to the transition piece: boat landing,

J-tube, platform and the transition piece was grouted to the foundation pile.

Figure 7 shows the “bunny ears”, the A2Sea installation vessel, the transition piece

being pre-fi tted with a J-tube and the installation of the transition piece.

The design for the support structures on Horns Rev was fully covered by the

owner of the wind farm: Elsam supplied all contractors with a complete pre-design,

which was to be prized and for which an installation method was to be drafted.

Search WWH ::

Custom Search