Environmental Engineering Reference

In-Depth Information

Reaction

M/C1

Output gears

Generator

Epicyclic

gears

Reaction

M/C2

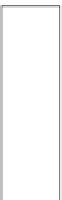

Figure 12 : Variable ratio gear arrangement.

found that at this size, it has worked quite successfully without heat dissipation

problems with a limited slip of up to 5%.

For larger powers, to provide better control and a bigger speed range with greater

energy capture without excessive losses, it is necessary to control the reaction with

a closed loop bypass branch comprising either a hydraulic pump and motor or an

electrical equivalent to recover the power which would otherwise be lost. With

such a system, torque may be monitored to enable transient referred inertia effects

to be eliminated. Variable ratio gears using this principle have been successfully

developed for powers up to 3.6 MW with synchronous generators driven by tur-

bines with speeds ranging from 60 to 100%. In effect, such gears allow turbine

speeds to increase when subject to a transient torque increase so that the excess

torque is absorbed by the increased kinetic energy in the rotor while the excess

speed is absorbed by the reaction member. Conversely, when the turbine torque

has a transient decrease its speed can be reduced by a ratio change to recover the

kinetic energy. For more sustained changes the gear ratio is changed accordingly

(see Fig. 12 ).

7 C onclusions

The purpose of this chapter is to show how the transient torque/speed charac-

teristics of a wind turbine affects the volume/weight of the drive train and the

benefi ts that accrue due to the use of epicyclic gears not only for reducing weight

and increasing compliance but also for their differential torque limiting properties.

Search WWH ::

Custom Search