Environmental Engineering Reference

In-Depth Information

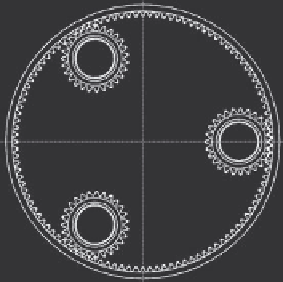

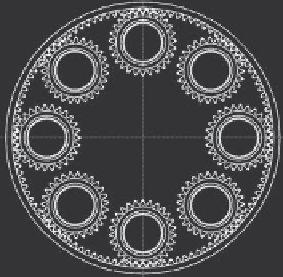

Various solutions have been used to provide load sharing for epicyclic gears

having more than three planets. The most widely used have employed a fl exible

annulus ring which subject to its tooth forces defl ects as shown in Fig. 6. However,

the maximum number of planets is usually limited to 6, because with greater num-

bers, load sharing becomes less effective as the defl ections decrease. Even though

more planets enable the ring thickness and weight to be appreciably reduced, it is

not enough to give the required defl ections without excessive stresses. In addition,

the planet spindles are straddle mounted in a carrier which requires rigid webs

between the planets to try and minimise its torsional wind up and the mal-distribution

across the meshing faces of the planet wheel teeth.

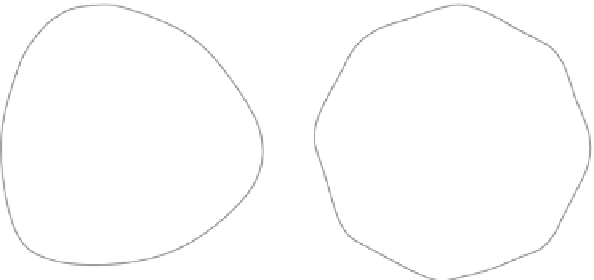

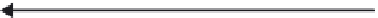

The main problem associated with fl exible annulus rings is that even with con-

stant torque, they are subject to fully reversed cyclic bending stresses due to the

outward and inward defl ections, with the passage of each planet (see Fig. 7).

The most logical location for fl exibility is in fact the planet spindle. Because it

serves as a mounting for an idler with zero torque, the relative load on the spindle

is always in a constant direction, whether or not the carrier is rotating. It follows

therefore that subject to constant torque, defl ection is static, and not subject to a

Figure 6 : Annulus ring bending defl ections. The defl ection curves should not be

offset laterally but located symmetrically so that they show the radial

inward and outward distortions of the respective 3 and 8 planet annulus

rings from their circular shapes.

Bending

stress

Angular distance between planets

Figure 7: Cyclic stress reversals.

Search WWH ::

Custom Search