Environmental Engineering Reference

In-Depth Information

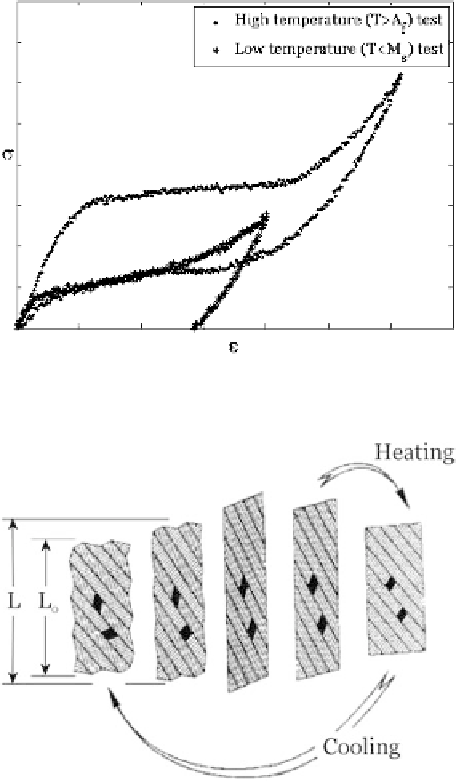

deformed heavily - up to 8% - under a small increase in loading. Upon unloading

the deformation remains. This can be observed in Fig. 10. Here no elaboration into

metallurgy is made, but Otsuka and Ren [20] offer a comprehensive review.

The nearly fl at part of the tensile

e

,

s

-curve is called the stress plateau. The defor-

mation is plastic, but recoverable by raising the temperature above a certain thresh-

old. Above this threshold the material is austenitic. Austenite has a cubic lattice

structure and therefore no variants. The material 'remembers' its undeformed shape

because the net shape of the austenite is the same as of the undeformed variants of

the martensite state. When the material is cooled down again the lattice structure

becomes multi variant martensite again. This deformation and heating cycle can be

observed in Fig. 11 and is called the shape memory effect (SME).

Figure 10: Stress-strain curves of a SMA wire at low and high temperatures.

Figure 11: The SME cycle in SMA (fi gure adapted from [87]).

Search WWH ::

Custom Search