Environmental Engineering Reference

In-Depth Information

from glass fi ber composites typical of wind turbines. For the bonding of glass fi ber

composites, the analysis is complicated by the development of large-scale bridging,

which requires that the fracture resistance is characterized in terms of the J integral.

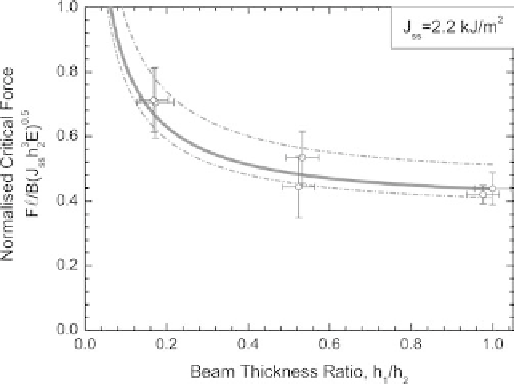

For the medium size specimens, the fracture load takes a steady-state value,

F

ss

,

after some crack extension. Figure 22 shows the predicted steady-state fracture

load, calculated from the steady-state fracture resistance data measured using

DCB-UBM specimens as a function of the thickness ratio of the two beams. The

measured steady-state strength values are superimposed as points. It is seen that

there is a good agreement between the model predictions and experimental strength

values of the medium scale specimens. The experimental results confi rm the trends

of the model predictions with respect to the effect of the thickness ratio of the

beams: reducing the thickness of the thin beams leads to a higher fracture load.

Furthermore, the predicted uncertainty of the strength of the medium size speci-

mens (due to the variation in the measured fracture resistance of the DCB-UBM

specimens) is of the same magnitude as found experimentally. Thus, the strength

scaling can be successfully achieved for large-scale bridging problems if the fracture

resistance data are analyzed by the J integral.

7.3.2 Cyclic crack growth of adhesive joints

Building upon the work described in Section 7.3.1 [70], Holmes

et al.

[ 71 ] inves-

tigated the cyclic crack growth behavior of adhesive joints in 1.2 m long medium

size beam specimens subjected to four-point bending. For this specimen confi guration,

a constant load amplitude gives a constant J amplitude,

Δ

J

, even though the crack

Figure 22: The load-carrying capacity of adhesive/glass fi ber composite medium

size specimens predicted using DCB-UBM data (solid line). Dashed

lines are predictions based on upper and lower values of

J

ss

. Experimen-

tal results from tests performed on the medium size specimens subjected to

four-point bending are shown as points; error bars represent the maximum

and minimum values of the measured steady-state force,

F

ss

[ 70 ].

Search WWH ::

Custom Search