Environmental Engineering Reference

In-Depth Information

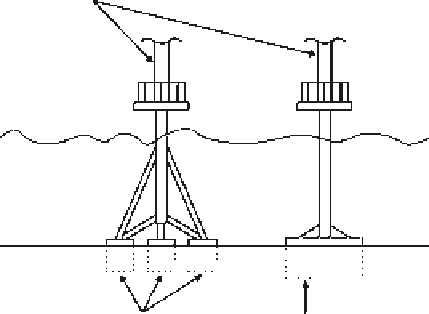

5.1.1 Level-controlled suction caisson foundations

Suction caisson foundations are currently utilized in the oil and gas industry for

sea depths up to 50 m. Their installation involves transporting the suction caisson

and placing it on the seabed. Water is then pumped out of the hollow dome in the

caisson resulting in the caisson sinking into the soil and being anchored in place

as shown in Fig. 9. Large hammers are not needed and the installation process

takes hours in contrary to days with monopile. As such, this is very conducive to

assembly-line operations.

There are risks to utilize the suction caisson foundation in wind power plants.

They include:

•

Performance under lateral dynamic wind loads - Two experimental wind tur-

bines were constructed, in Denmark and England, using suction caisson foun-

dations. Results indicate that performance under long-term lateral dynamic

loads remains a key issue preventing large-scale utilization of suction caissons

in deeper sites.

Proper tower installation - Caisson verticality tolerance is not necessary in the

•

oil and gas industry. However, wind turbine tower installation requires control-

ling the foundation top surface verticality within 1°. One degree off on vertical-

ity could result in several meters of eccentricity at the hub height. It not only

results in increased over-turning moment, which is a key design criterion, but

also affects turbine performance. One EU OEM suffered an installation failure

for a near-shore test turbine because of the verticality problem from a hard spot

under one side of the caisson bottom edge during the suction process.

5.1.2 Jetting and grouting in deep sea piling

With conventional monopile foundation, heavy vessels needed for pile driving

account for 20% of the total foundation costs. Jetting and grouting eliminate the

Turbine Support Structure

Water Surface

Seabed

Caissons

Caisson

Figure 9 : Level-controlled suction caisson foundations [ 14 ].

Search WWH ::

Custom Search