Environmental Engineering Reference

In-Depth Information

P

bulb

= 900 W, where the blade settings are defi ned as shown in Fig. 28 at the

blade tips. The rear wind rotor never counter-rotates against the front wind rotor

at the lower wind velocity

V

because not only the rear wind rotor cannot generate

the suffi ciently counter-rotational torque

T

R

corresponding to

T

F

of the front wind

rotor but also the outer armature pulls the inner armature by the magnetic force.

With the increase of the wind velocity, the rear wind rotor with

b

R

larger than 20°

begins to counter-rotate successfully. On the contrary, the rear wind rotor with

b

R

=

10° never change the rotational direction and is in the blowing mode because the

rear blade with the excessively larger angle of attack cannot generate the fruitful

counter-rotational torque due to the fl ow stall on larger scale. Judging from the

counter-rotation expected to this type unit, the rear wind rotor with

b

R

= 20° may

be acceptable within the measured data.

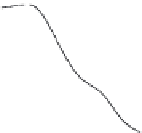

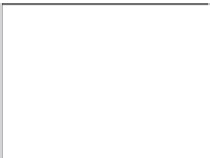

Figure 29 shows the effect of the bulb load on the operating conditions at the blade

setting angles

b

F

=

b

R

= 20°. The load

P

bulb

affects obviously the rotational speed of

Rear Rotor

b

F

Wind direction

b

R

Front Rotor

Figure 28: Blade setting angles.

90

6

P

bulb

b

F

=20deg.

b

R

=20deg.

60

423

1023

60

4

P

bulb

60

423

1023

30

2

0

0

750

600

N

F

300

600

P

bulb

N

F

N

R

P

bulb

60

423

1023

0

450

60

423

1023

-300

300

b

F

=20deg.

b

R

=20deg.

-600

150

N

R

-900

0

0

5

10

15

20

0

5

10

15

20

V

m/s

V

m/s

Figure 29: Effect of the bulb load on the operation conditions.

Search WWH ::

Custom Search