Environmental Engineering Reference

In-Depth Information

estimated to be more than 50 $/kAm, which may be acceptable in niche rotating

machine markets, but too expensive for the wind market.

5.2 2G HTS wire technology

The new 2G wires are based on the superconducting material YBa

2

Cu

3

O

x

nor-

mally referred to as YBCO-123 or simply YBCO. The structure and manufactur-

ing method of 2G HTS wire is very different form that of 1G wire. YBCO was

one of the fi rst HTS materials to be discovered and is easily made in bulk form

by growing a crystal in a similar manner to silicon. Development of YBCO-based

wire began in the 1990s by attempting to deposit a crystal of YBCO onto a metal

substrate tape. This technique has now been extensively developed by several

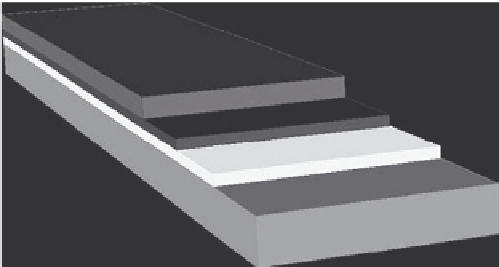

manufacturers using a number of different processes. The wire structure consist

of a substrate, typically a Nickel-Tungsten alloy, a very thin buffer layer onto

which is deposited the YBCO superconductor to a thickness of 1-5 µm. Often an

outer copper layer is added for stability. The overall wire thickness is between 0.1

and 0.2 mm thick depending on the manufacturer and product. The coatings are

deposited on a wide strip of the substrate and then slit to the required tape width.

This gives fl exibility in the fi nal width and current carrying capacity of the HTS

tape, the most common being 4 mm for compatibility with 1G HTS materials, and

12 mm for higher current carrying capacity. A simplifi ed wire structure is shown in

Fig. 5, some processes introduce additional buffer layers. It is also possible to join

two of these tapes back to back to produce a symmetrical duplex tape.

This type of HTS wire has the potential for volume production at low cost. It

does not require the large fl oor space the 1G wire need for the drawing process,

since the 2G process can be reel to reel, and once the correct process parameters

are set up production remains almost entirely automated.

HTS materials are intrinsically anisotropic, and their sensitivity to magnetic fi eld

depends on the direction of the fi eld relative to the surfaces of the HTS tape. It has

been necessary to develop methods in the manufacturing process that minimise the

effect of this anisotropic behaviour [32].

Copper

HTS

Buffer

Substrate

Figure 5: Simplifi ed 2G wire structure - thickness scale exaggerated.

Search WWH ::

Custom Search