Environmental Engineering Reference

In-Depth Information

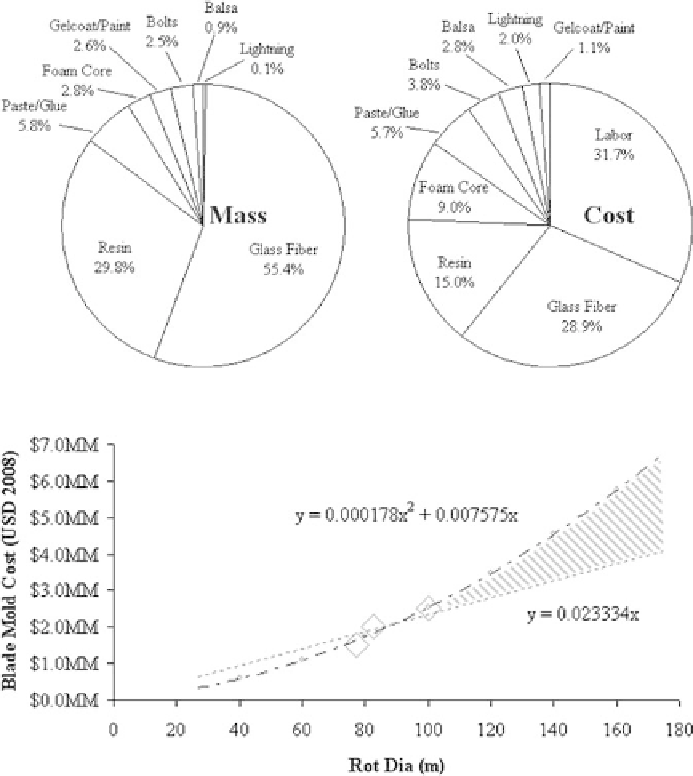

Figure 19: Mass and cost breakdown for nominal GFRP blades.

Figure 20: Blade mould tooling costs for nominal GFRP blades.

and lower blade half moulds. The mould halves are hinged together to facilitate the

fi nal closure and bonding operation for normal blade production.

As shown in Fig. 20, the cost of a blade mould for one of today's typical 1

−

3 MW

WTs is around $2MM or more. A single mould can manufacture 600

1000 blades

before it will require refurbishment at a cost of $120K or more. Moulds can usu-

ally be refurbished at least two to three times before new replacements are needed

[27]. These trends imply that larger turbines in the 7

−

−

10 MW size would require

moulds that cost $4

6MM unless alternative technologies can be found. In reality

moving beyond rotor diameters of 120

−

65 m long blades ignoring

the hub diameter) using GFRP blade construction technology is generally viewed

as too heavy and impractical so that new large blade technology will be needed to

improve this trajectory [58].

−

130 m (i.e. 60

−

Search WWH ::

Custom Search