Environmental Engineering Reference

In-Depth Information

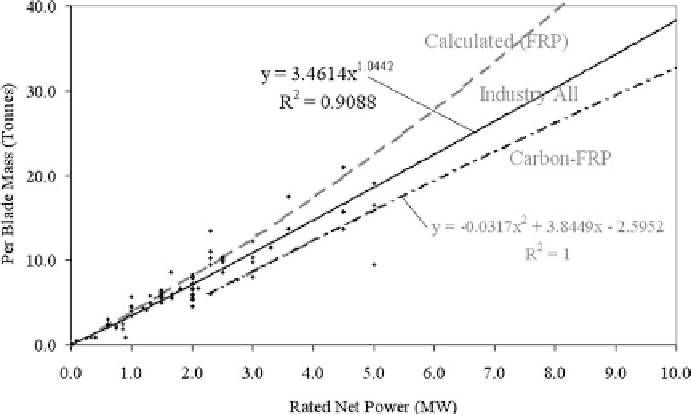

Figure 18: Blade mass - 10-turbine analysis compared to industry study set.

sketch /C/ and for winds above rated wind speed. The maximum defl ection outline

shows another view of the importance for the minimum tower clearance discussed

earlier in this chapter.

Figure 18 shows the 10-turbine analysis group (i.e. calculated), a curve fi t for

the industry study set using GFRP, and the industry study set for carbon spar and

GFRP hybrids. Clearly if one just scaled today's average technology to 10 MW,

the individual blade mass would be in excess of 40 tonnes. Since the larger

machines in the industry study set tend to incorporate a carbon spar or utilize some

form of an advanced GFRP construction, the industry trend projects the 10 MW

blade to be less than 40 tonnes. A carbon

−

GFRP hybrid blade should be able to

achieve 32

34 tonnes per blade. Based on the past industry progress going from

1 to 5 MW, and with new technology yet to be discovered, it may be possible for a

10 MW blade to be designed in the 25 tonne range.

The majority of today's blades are made from GFRP incorporating either a box

spare or shear web construction. Figure 19 shows the typical mass and cost break-

down for an average sample of blades incorporating shear web construction [26].

The glass fi bre and epoxy or vinyl resin comprises the vast majority of the mass.

Manufacturing these blades requires a large amount of man-hours such that labour

accounts for nearly 1/3 of the total cost for a blade.

Today's mainstream blade construction technology requires signifi cant invest-

ment in mould tooling to form, cure and assemble large WT blades. A steel sub-

frame and backing structure is used build-up the basic upper and lower mould

shell tools. Curing heaters (electrical or temperature controlled fl uid channels) are

arranged throughout the surfaces prior to establishing the fi nal mould surfaces.

These are typically completed using a prototype blade (i.e. plug) to provide a form

for the fi nal tool surface made from high temperature epoxy resin within the upper

−

Search WWH ::

Custom Search