Environmental Engineering Reference

In-Depth Information

A yaw system maintains the horizontal rotor axis pointing upstream into the wind.

A power conversion system that converts the low-speed rotational energy into

suitable shaft power to drive an electrical generator.

A tower and foundation structure to support the rotor and generator system at a

height that harvests the most amount of energy for an acceptable capital cost.

An electrical power distribution system that supplies the energy to the consumer

in compliance with local grid code and system requirements.

4.2.2 Mechanical

electrical power conversion architecture

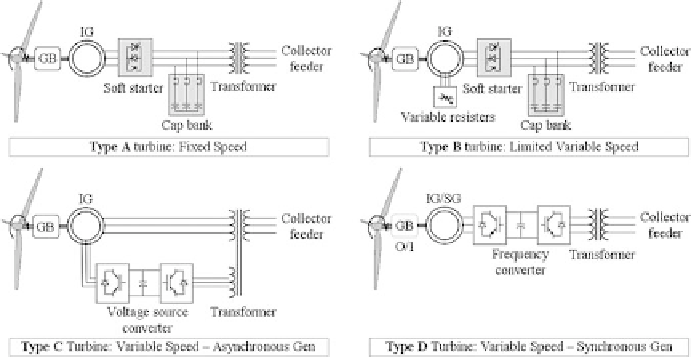

Figure 9 shows the four main types of WT architecture that have been employed

according to Wojszczyk

et al.

[21]. Types A and B are older and less prevalent

confi gurations, while Types C and D comprises the mainstay of modern MW

WT offerings.

Type A is the oldest and utilizes a squirrel cage induction generator (SCIG)

directly coupled to the electrical grid. It may incorporate a soft starter to limit in-

rush current during start-up conditions. The rotor is connected to the generator

through a gearbox and can often run at two different (but constant) speeds. This is

achieved by changing the number of poles of the stator winding. The generator

always consumes reactive power, and therefore this has to be compensated by

capacitor banks to optimize the power factor and maintain the voltage level.

Type B introduces a variable resistor in the rotor circuit of a wound rotor induction

generator (WRIG). This can be done using slip rings or the resistors and electronics

can be mounted within the rotor. The variable resistors control the rotor currents to

maintain constant power output and allow the WT to have dynamic response during

grid disturbances. Some degree of self-protective torque control and energy capture

range is provided by

−

10% speed variation.

Type C is known as the double fed induction generator (DFIG). It improves on the

Type B design by adding variable excitation (instead of resistance) to the rotor cir-

cuit. The generator stator winding is directly connected to the grid and the rotor

±

Figure 9 : The four main types of WT mechanical

−

electrical power conversion.

Search WWH ::

Custom Search