Environmental Engineering Reference

In-Depth Information

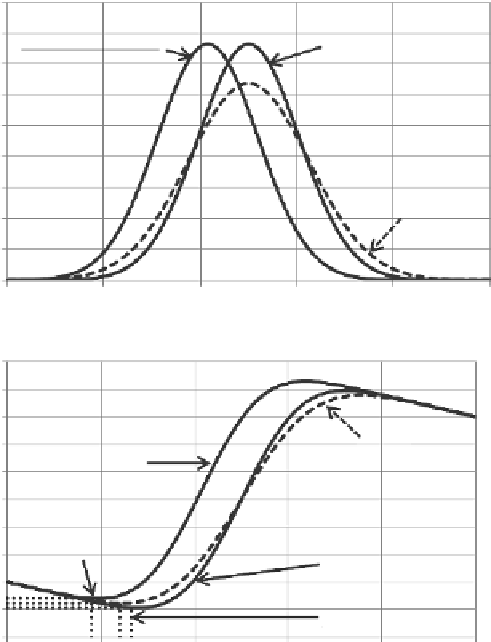

0.045

0.040

0.035

0.030

0.025

0.020

0.015

0.010

Updated:

x = 40

kPa

, n = 10

Updated:

x = 50

kPa

, n = 10

μ′′

T

X

= 50.0 kPa

σ′′

T

X

= 10.4 kPa

μ′′

T

X

= 41.5 kPa

σ′′

T

X

= 10.4 kPa

Prior:

μ′

T

X

= 50 kPa

σ′

T

X

= 12.5 kPa

0.005

0.000

0

20

40

60

80

100

x

(kPa)

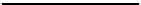

100,000

90,000

80,000

70,000

60,000

50,000

40,000

30,000

20,000

Prior

Updated:

x = 40

kPa

, n = 10

x

*

Opt

= 18.0 kPa

E

(

C

)

Min

= $14,002

Updated:

x = 50

kPa

, n = 10

x

*

Opt

= 26.5 kPa

E

(

C

)

Min

= $10,606

10,000

0

0

20 40 60

Design undrained strength,

x

* (kPa)

80

100

Figure 13.25

Updated results for two different results from testing of compacted fill.

strength,

x

*, a

n

d the expected total cost in two ways. First, the mean value for

X

will be

updated from

x

. Second, the total standard deviation for

X

will be reduced with the magni-

tude of the reduction increasing with increasing

n

.

*

The optimal design value in a posterior analysis is shown in

Figure 13.25

for two dif-

ferent possible QA/QC test results. Note that the updated optimal design value incre

a

ses

and the expected cost decreases from the prior analysis if the measured sample mean,

x

, is

equal to the prior mean of 1000 psf. This result occurs because we have reduced uncertainty

in

X

by obtaining 10 measurements, meaning that a less-conservative design is possible.

Conversely, the updated optimal design value decreases and the expected cost increases

from the prior analysis if the measured sample mean is 200 psf lower than the prior mean

(800 vs. 1000 psf). In this case, while we are more certain about

X

, the updated mean value

for

X

is lower; so, a more conservative and costly design is required.

*

Note that this result where the uncertainty in the updated distribution for the model parameter always decreases

with added information is not general; the uncertainty in the updated distribution for a parameter can increase

with added information (e.g.,

Figure 13.10

).

Search WWH ::

Custom Search