Environmental Engineering Reference

In-Depth Information

(a)

50

FS

1

=

30

(b)

50

Reliability index β

=

R

/

r

β-ellipse

45

40

35

30

25

45

40

FS

1

=

20

FS

2

=

1.60

FS

2

=

1.48

FS

2

=

1.30

FS

2

=

1.15

1-σ dispersion

ellipse

r

35

30

25

R

FS

1

=

10

20

15

10

5

0

20

15

10

5

0

Design point (28.0, 28.3),

the most probable failure

point

0

10

20

30

40

0

10

20

30

40

α(°)

α(°)

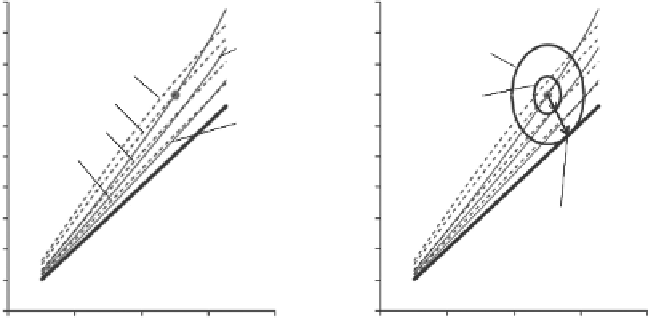

Figure 9.15

(a) Contours of

FS

1

and

FS

2

and the mean-value point where

FS

1

=

30.1 and

FS

2

=

1.48; (b) dis-

persion ellipses in the space of

α

and

ϕ

. The plots are for i

=

0,

k

s

/

k

n

=

0.1, p

=

1 MPa,

K

0

=

1.5,

R

=

2 m,

h/R

=

0.85, and

γ

=

0.027 MN/m

3

.

clearly shows that the mean

FS

1

is only as safe as the mean

FS

2

, despite its being 20 times

higher than

FS

2

, because the same (α, ϕ) point for both is at the same distance from the LSS

(where

FS

1

=

FS

2

= 1), which separates the safe combinations (FS > 1.0) of values of (α, ϕ)

from the unsafe combinations (

FS

< 1.0) of (α, ϕ).

This problematic aspect of using safety factors can be avoided if one uses the reliability

index, as shown in

Figure 9.15b.

The FORM computes a reliability index, β, which is the

distance from the safe mean-value point (α, ϕ) = (25°, 35°) to the most probable failure point

(α = 28.01°, ϕ = 28.33°), also called the design point, in units of directional standard devia-

tions. The same β value is computed regardless of whether

FS

1

or

FS

2

is used to define the

LSS FS = 1.0.

Figure 9.16a

shows the results of SORM reliability analysis on the foundation of FORM

results. The FORM results were obtained automatically using the practical constrained

optimization approach of Low and Tang (2007). The SORM procedure in the spreadsheet

was described in Chan and Low (2012a). The parameters α, ϕ,

k

s

/

k

n

,

p

, and

K

0

(defined in

connection with

Equation 9.9)

are assumed to be normally distributed random variables,

with mean values μ and standard deviations σ as shown in the labeled columns. Other input

values (with zero standard deviations) are

i

= 0,

R

= 2.0 m,

h/R

= 0.85, and γ = 0.027 MN/

m

3

. The mean ratio of normal force N to wedge weight W is 71 for this case. The mean

FS

1

= 30.1, and mean

FS

2

= 1.48, with α = 25°, ϕ = 35°,

k

s

/k

n

= 0.1,

p

= 1 MPa, and

K

0

= 1.5.

Hence, at these mean input values, the wedge is safe. However, wedge failure will occur

when the mean values descend/ascend to the design point values shown in the

x

* column

in

Figure 9.16a,

analogous to

Figure 9.1

but in five-dimensional (5D) space. The design

point values are α* = 28.01°, ϕ* = 28.34°, (

k

s

/k

n

)* = 0.1,

p

* = 0.9975 MPa, and

K

0

* = 1.474.

The wedge is on the verge of failure at these design values, mainly due to a greater semi-

apical angle (α* = 28.01° > mean α value of 25°) and a lower friction angle of the joints

(ϕ* = 28.34° is smaller than the mean ϕ value of 35°). The distance from the safe mean-value

point to this most probable failure combination of parametric values, in units of directional

standard deviations, is the reliability index β, equal to 2.684 in this case.

The

n

in

Equation 9.3

are the dimensionless equivalent standard normal random variables

under the square root sign of

Equation 9.2,

and their values in

Figure 9.16a

suggest that ϕ and

Search WWH ::

Custom Search