Graphics Programs Reference

In-Depth Information

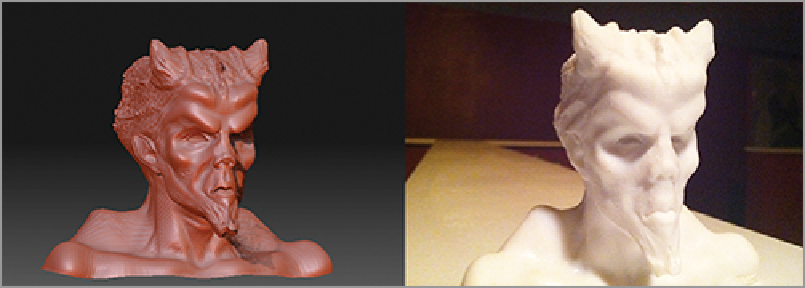

Image courtesy of Z Corporation

Figure 11-5:

This demon bust was printed by artist Nick Benson on a ZCorp 510 3-D printer.

3-D Milling

3-D mills or

CNC milling machines

are generally used for larger objects than are possible to print on a 3-D

printer. They are somewhat faster and yet reproduce less detail by virtue of the material employed and the

fact that a carving approach is used rather than an additive building process. The mill can operate in multiple

axes, allowing a movable robotic head to carve away the shape of 3-D data in a block of material (

Figure

11-6

)

. 3-D milling is generally used for large-scale objects and the detail is generally limited by the side

of the milling head and the quality of base material being milled. We do not focus much on milling in this

chapter because you will almost always be printing with a stereolithography machine or a 3-D printer to get

the level of detail you will want in your figures.

One drawback to 3-D milling is its inability to reproduce undercuts. Undercuts are areas of a shape that

dip back and underneath, like the nostrils or insides of ears (

Figure 11-7

)

. Because a mill carves the shapes

out, you cannot mill an undercut as easily as you can print an object with an undercut.

Figure 11-8

shows

a life-sized King Kong milled by Gentle Giant for the premiere of King Kong in New York City. The data

used was the actual Kong model, reworked and detailed in ZBrush. This amazing project was overseen by

Gino Acevedo of Weta Workshop for Gentle Giant Studios.

Figure 11-6:

A Comet robot milling machine

Search WWH ::

Custom Search