Graphics Programs Reference

In-Depth Information

cause each layer is merely microns thick, a high degree of detail can be reproduced. When a model is prop-

erly decimated and oriented on the printer bed, details as small as skin pores are easily reproduced. Decim-

ation is the process of lowering the overall polygon count while retaining all the model details. Decimation

is integral to the 3-D printing workflow, and we will look at it in-depth later in this chapter.

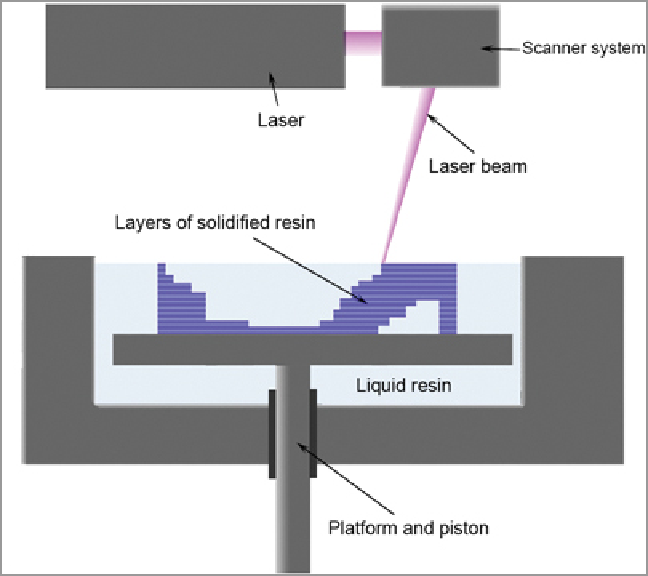

Figure 11-2:

This image illustrates the process by which a part is “grown” in a 3-D printer tray.

©Materialgeeza

On the modern generation of high-end 3-D printers, I have seen models printed with this machine that

needed little to no cleanup before being molded for production. Often the single generation loss of detail

introduced by the molding process was enough to reduce the remaining surface lines from the build.

Figure

11-3

shows a mesh detail from a superhero costume 3-D printed by Gentle Giant Studios. The level of detail

here is phenomenal and the build lines are essentially invisible! Build lines are created by the various layers

of extrusion material, show up as fine lines on the print, and need to be removed by a light cleanup.

Some printers use a different material than the resin used by the Objet printers. The ZCorp printer line

uses a material mix that can also support the printing of some color from the model (

Figure 11-4

).

Figure

11-5

shows a design by Nick Benson printed on the ZCorp Spectrum 510.

Figure 11-3:

Costume detail from an Objet Eden print at 12 inches tall

Search WWH ::

Custom Search