Biomedical Engineering Reference

In-Depth Information

wall material layer. Some linoleic acid molecules would be replaced with the saturated groups

of the ascorbates and the replacement would increase the stability of linoleic acid toward the

oxidation.

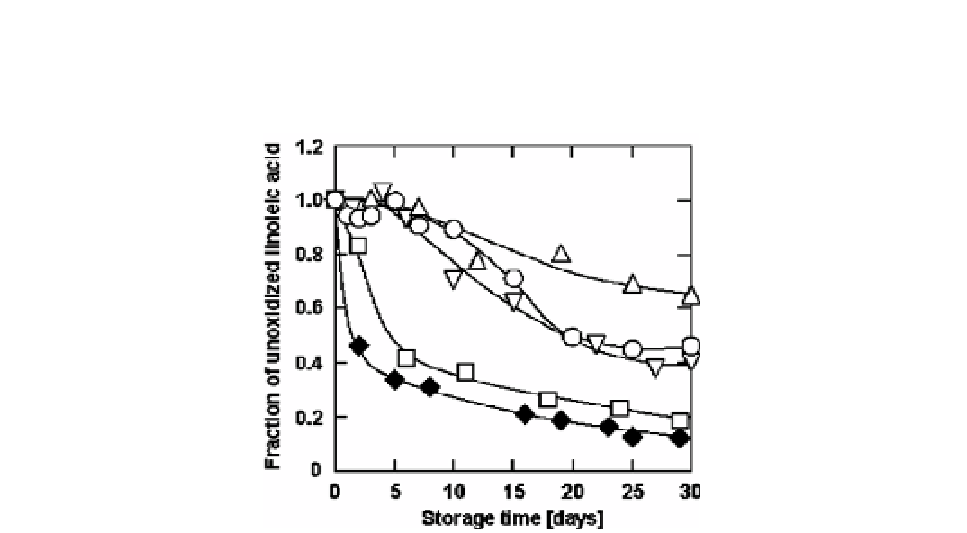

Figure 19. Effect of the addition of various saturated acyl ascorbates to linoleic acid on the oxidation of

linoleic acid encapsulated with maltodextrin; (

) no addition, (

) octanoyl, (

U

) decanoyl, (

V

) lauroyl

and (

{

) palmitoyl ascorbate.

The molar ratio of the saturated acyl ascorbate to linoleic acid was 0.1.

The oxidation was observed at 37

o

C and a relative humidity of 12%.

Figure 20. Median diameters of oil droplets in emulsions prepared with various saturated acyl

ascorbates.

Arachidonoyl ascorbate, which was a polyunsaturated acyl ascorbate, was

microencapsulated with various wall materials, which were maltodextrin, gum arabic and

soluble soybean polysaccharide, by spray-drying [33]. Arachidonic acid was also

microencapsulated with the wall materials in the presence or absence of ascorbic acid. The

oxidative stabilities of the microencapsulated arachidonoyl ascorbate and arachidonic acid

were then examined at 37

o

C and 12% relative humidity. For comparison, the oxidative

stabilities of the nonencapsulated arachidonoyl ascorbate and arachidonic acid were also

observed under the same conditions. The median diameters of the oil droplets in the O/W