Biomedical Engineering Reference

In-Depth Information

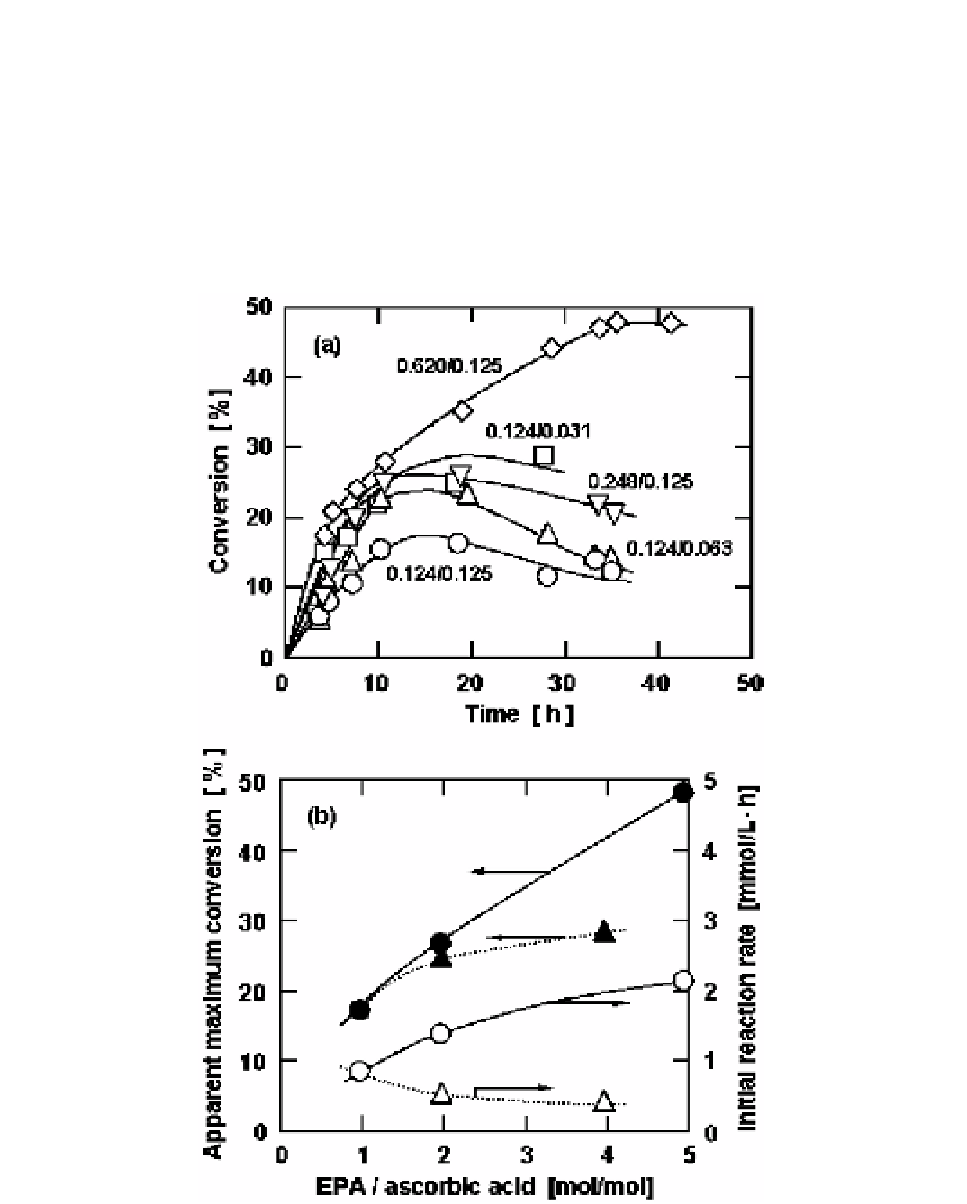

ascorbic acid was changed (open triangle), the reaction rate became slower at the higher ratios

due to the decrease in the initial ascorbic acid concentration. The relationships between the

maximum conversion and the molar ratio for the condensations of ascorbic acid and saturated

fatty acids with various chain lengths from 6 to 12 were examined [24]. There was no

significant difference in the relationship among the fatty acids tested. The maximum

conversion was higher at the higher molar ratio. Since high conversion and a lower amount of

unreacted fatty acid were favorable for the purification process, the molar ratio of 5 would be

the most appropriate for production of acyl ascorbate in the present reaction system.

Figure 3. Lipase-catalyzed condensation of eicosapentaenoic acid (EPA) and ascorbic acid at their

various molar ratios in acetone at 55

o

C. (a) Time courses for conversion of 6-

O

-eicosapentaenoyl

ascorbate: the amounts of EPA/ascorbic acid (mmol/mmol) added in 2.5 ml acetone are shown in the

figure. (b) Dependence of apparent maximum conversion (closed symbols) and initial reaction rate

(open symbols) on the EPA/ascorbic acid molar ratio. Circles and triangles represent the results

obtained at the fixed amounts of ascorbic acid (0.125 mmol) and EPA (0.124 mmol), respectively. The

curves were empirically drawn.