Biomedical Engineering Reference

In-Depth Information

mean time, an examination of emission from diesel engine by using different ratio of blending

biodiesel was carried out under the support of Environmental Protection Administration,

Taiwan (Figure 21). It showed that biodiesel also produces fewer particulate matter, carbon

monoxide, and sulphur dioxide emissions.

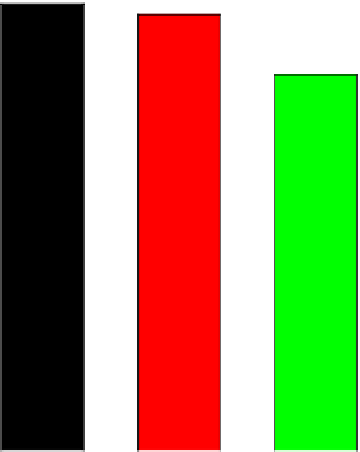

In addition, when the whole life cycle analysis (LCA) of biodiesel from production of the

biomass via conversion to use as an energy source illustrated a significant reduction on green

house gas emission (see Figure 22). In summary, LCA is an important tool for describing

environmental (dis)advantages and therefore serves in decision-making. It can be

complemented by a socioeconomic assessment to ensure complete and sustainable long-term

production of biodiesel.

7. Conclusion

Biodiesel (fatty acid alkyl ester) is a cleaner-burning diesel replacement fuel made from

natural, renewable and biodegradable sources. It is a stable diesel which performs reliably in

all diesel engines without any modification, is mixable with petroleum diesel fuel, easy to

make and safe to handle. Of the several methods available for producing biodiesel,

transesterification of natural oils and fats is currently the method of choice. Biodiesel has

become more attractive recently because of its environmental benefits and the fact that it is

made from renewable resources. The remaining challenges are its cost and limited availability

of fat and oil resources. There are two aspects of the cost of biodiesel, the costs of raw

material (fats and oils) and the cost of processing. The cost of raw materials accounts for 60

to 75% of the total cost of biodiesel fuel. The use of other materials such as waste cooking oil

700

600

500

400

300

200

100

0

Diesel

B5

B20

B100

Figure 22. Comparison of Net CO

2

Life Cycle Emissions for Petroleum Diesel and Biodiesel Blends.