Biomedical Engineering Reference

In-Depth Information

•

The production process and the other materials used in this process.

•

Post-production parameters.

All biodiesel production facilities should be equipped with a laboratory so that the quality

of the final biodiesel product can be monitored. It is also important to monitor the quality of

the feedstocks. One strategy used by many producers is to draw a sample of the oil (or

alcohol) from each delivery and use that sample to produce biodiesel in the laboratory. This

test can be fairly rapid (1 or 2 hours) and can indicate whether serious problems are likely in

the plant. Measuring feedstock quality can usually be limited to acid value and water content.

To monitor the completeness of the reaction according to the total glycerol level specified in

ASTM D 6751 requires the use of a gas chromatograph and a skilled operator. Large

producers will find that having this equipment on-site is necessary. Commercial laboratories

(i.e. Magellan Midstream Partners) are available that can analyze the samples but the cost is

$80-$150/test and the time required may be several days. Smaller producers will need to use a

more robust production process involving extra methanol and probably multiple reaction

steps. Then the product quality can be monitored through periodic testing by an outside

laboratory. To circumvent this, comparison to a reaction and product known to meet national

standards is needed.

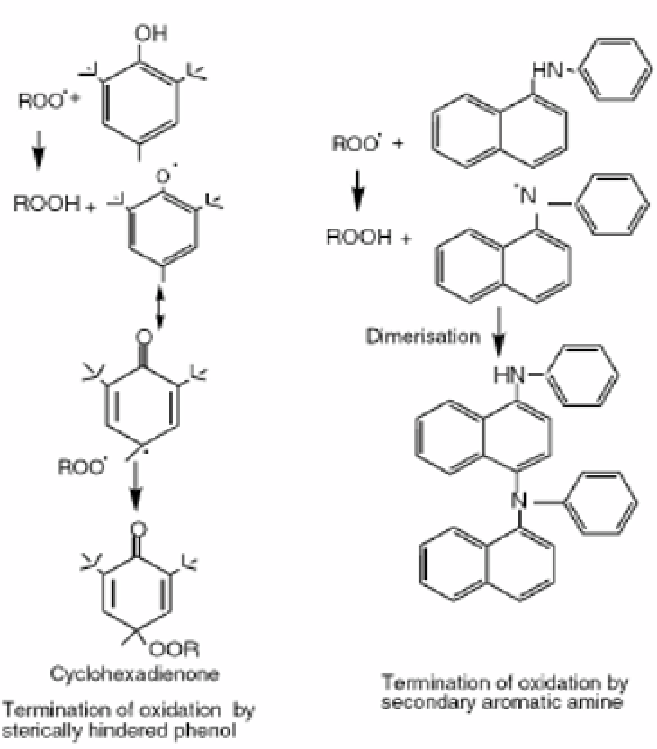

Figure 19. Mechanism of antioxidants reaction.