Biomedical Engineering Reference

In-Depth Information

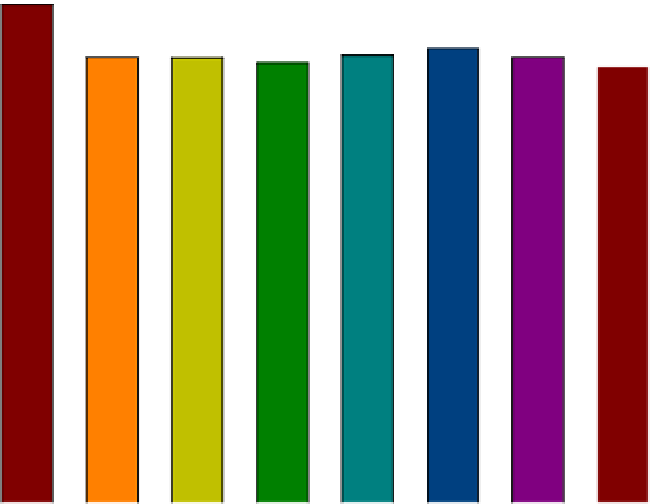

20000

Diesel

18000

Yellow

grease

Edible

Tallow

Inedible

Tallow

Canola

Soybean

Recycle oil

Lard

16000

14000

12000

10000

8000

6000

4000

2000

0

Figure 15. Heating value of diesel and varied biodiesel (B100) fuels.

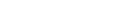

Table 13. Summary of alternative transesterification procedures

Transesterification

Methods

Maximal

yield (%)

Catalyst

(%)

Temp.

(

℃

)

Time

(minute)

Alcohol:oil

ratio

Solid super base catalyst

93

1.5

70

150

9:1

In situ (without oil extraction step)

87

1.0

60

60

-

Supercritical alcohols

99

0

200-250

40

50:1

Enzymatically in the presence of

supercritical CO

2

70

0

45

480

5:1

4. Manufacturing Art

There are many methods of producing biodiesel. In this section, a few of these methods

are described in detail. Other methods are often combinations or slight deviations from the

methods described. As an example, Table 13 includes a summary of a variety of methods to

produce biodiesel. Most biodiesel production facilities utilize the conventional methods of a

batch or continuous reactor process. These processes utilize the classic ingredients discussed

above. Typically, the proportions used are:

•

Reactants: Fat or Oil (e.g. 100 kg soybean oil)

•

Primary Alcohol (e.g. 10 kg methanol)

•

Catalyst: Mineral Base (e.g. 0.3 kg sodium hydroxide)

•

Neutralizer: Mineral Acid (e.g. 0.25 kg sulfuric acid)