Biomedical Engineering Reference

In-Depth Information

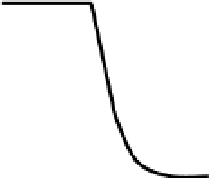

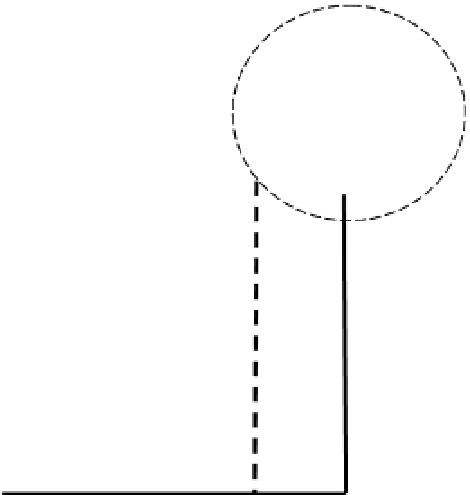

Resistances associated to either of these transfer steps caused that substrate concentration

in the site of biochemical reaction is lower than in the gas phase or in the bulk liquid and,

therefore, the overall rate of biological treatment decreased (Figure 3). The relative

importance of these resistances in providing a process rate limitation is influenced by

numerous factors, including the size and shape of the biomass aggregates, fluid and substrate

properties, intrinsic reaction kinetics of the microorganisms and the hydrodynamics of the

bulk phase. In this aspect, agitation and aeration are generally used to improve mass transfer

rate in reactors due to the hydrodynamic turbulence caused by them. They also can be used to

improve the performance of the reactors by enhancing the fluid mixing and controlling the

thickness of biofilms (Ebrahimi et al., 2006). However, the energy required to induce and

maintain the physical mass transfer pathways in the systems should be also considered.

A

(g)

+ B

(l)

→

R

(g)

A

(g)

+ B

(l)

→

R

(g)

C

Ai

C

Ai

C

B

C

B

P

A

P

A

C

A

C

A

C

Bs

C

Bs

C

As

C

As

P

Ai

P

Ai

Gas

phase

Gas

phase

Gas

phase

Gas

phase

Liquid

phase

Liquid

phase

Liquid

phase

Liquid

phase

Biomass

Biomass

Figure 3. Substrates profiles caused by the mass transfer resistances (P

A

: Partial pressure of A in the gas

phase; P

Ai

: Partial pressure of A in the interphase gas-liquid; C

Ai

: Concentration of A in the interphase

gas-liquid (in equilibrium with P

Ai

); C

A

, C

B

: Concentration of A and B in the bulk liquid; C

As

, C

Bs

:

Concentration of A and B inside the biomass aggregate).

Generally, agitation and aeration rates are the most critical parameters used for scale-up

biological treatment process and play significant roles in determining the efficiency of the

process. For this reason, great efforts were carried out in order to obtain engineering

correlations to the scaling-up of biochemical reactors which allows calculating shear stress

and mass transfer coefficients as a function of operational parameters such as superficial gas

and liquid velocities, stirring velocity or energy input.