Biomedical Engineering Reference

In-Depth Information

the drag force exerted by the ambient fluid and the viscoelastic force of the aqueous polymer

solution. Under the appropriate balance of the forces, a stretched jet of aqueous polymer

solution forms in the immiscible liquid. Subsequently, the jet becomes unstable due to the

interfacial tension and fragments into individual droplets. The phenomenon of droplet

breakup via jetting is explained by Rayleigh-Plateau hydrodynamic instability [33]. As shown

in Figures 2 and 4, we can obtain smaller droplets by increasing the velocity of ambient co-

flowing liquid, decreasing the velocity of aqueous polymer solution, and decreasing the

diameter of needle [28,34]. It is easy to understand the effect of velocities of liquids and

diameter of the needle on the diameter of the resultant droplets.

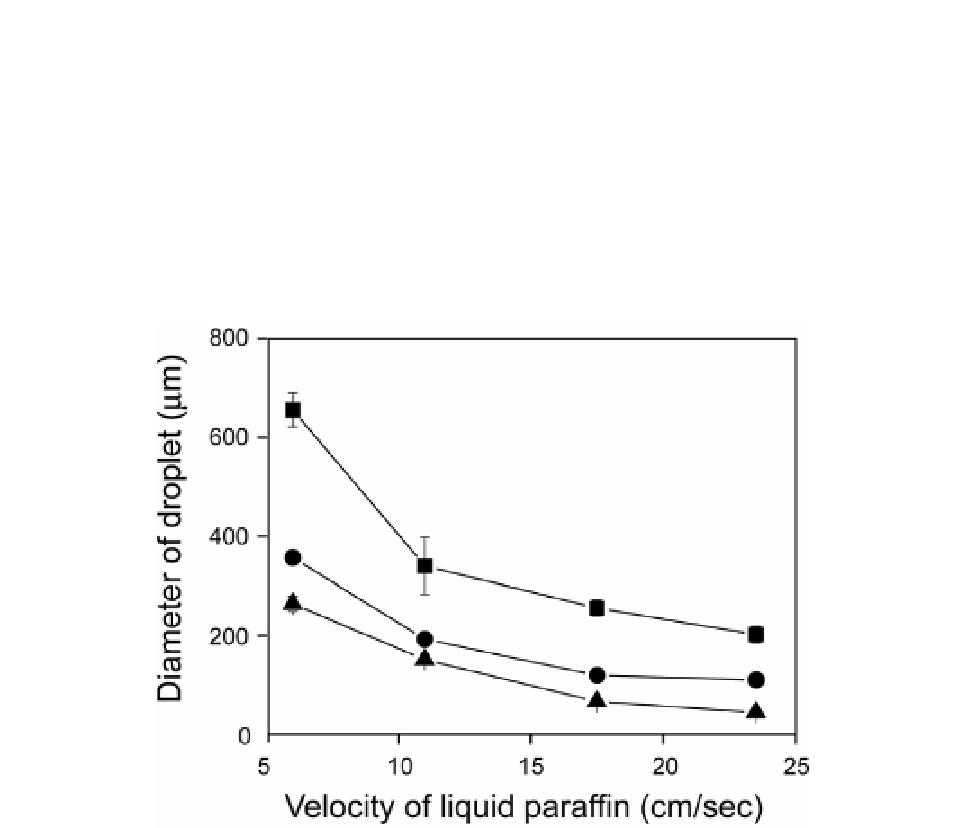

Figure 4. Droplet diameter as a function of liquid paraffin for three aqueous solution differing in

viscosity: (■) 1.0, (●) 36, and (▲) 194 mPa⋅s. Aqueous solutions were extruded at a velocity of 1.2

cm/sec from a needle with a 300 μm i.d. Error bars represent SDs (Reproduced with permission, from

Sakai S et al. Biotechnol Prog. [34] @ 2005 American Institute of Chemical Engineers).

In addition to these factors, viscosity of a polymer solution is also a factor influencing the

diameter of the resultant droplets [34]. As shown in Figure 4, at the velocities of liquid

paraffin and aqueous solution which were 6.0 cm/sec and 1.2 cm/sec, respectively, the

droplets obtained from the aqueous solution of 1.0 mPa⋅s were the largest and their mean

diameter was 655 μm. Droplet diameter decreased with the increasing viscosity of the

aqueous solution. This tendency was kept even under conditions of a faster flow rate of liquid

paraffin. At a liquid paraffin velocity of 23.5 cm/sec, the diameters of droplets were 202, 110,

and 44 μm for aqueous solutions of 1.0, 36 and 194 mPa s. The smaller droplets generated

from a higher viscous solution results from the formation of a thinner ligament from a higher

viscous solution [34]. This means we can obtain the microcapsules with a higher mechanical

strength resulting from a synergy of reduction in diameter and a tightening of gel microscopic

structure using a smaller quantity of ambient fluid. The droplet breakup method using liquid

paraffin as the ambient liquid also is advantageous because it only damages a small

percentage of cells. The undamaged percentages of the cells enclosed in the droplets of 110