Biomedical Engineering Reference

In-Depth Information

uses air as an ambient fluid (Figure 1a). The inner needle is positioned upstream in the

vicinity of a coaxial outer tubule in which the water-immiscible liquid (liquid paraffin is used

in our study) is flowed. Formation of the droplets smaller than the needle diameter is achieved

at the tip of a stretched aqueous solution ligament much thinner than the needle diameter, that

is, via jetting (Figure 3) [28]. When a disperse phase is injected from a capillary into an

immiscible liquid flow at laminar flow, two different droplet breakup modes are observed.

Specifically, droplets either form close to the capillary tip, called dripping, or break up at the

tip of a stretched liquid jet, called jetting [29]. The formation of a jet thinner than the needle

diameter is interpreted as a consequence of being stretched by the drag force exerted by the

ambient co-flowing fluid. In general, the behavior of the extruded solution into the co-flowing

fluid is affected by a complicated balance of three forces [30-32]: the interfacial tension force,

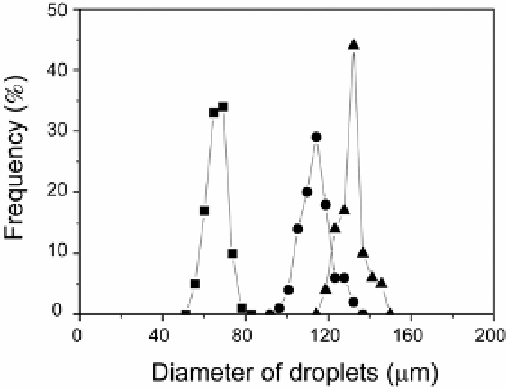

Figure 2. Size distribution of 2.0 wt% sodium-alginate extruded from a needle with 480 μm i.d., 700

μm o.d. at (■) 1.2 cm/sec, (●) 2.6 cm/sec, and (▲) 4.7 cm/sec into a co-flowing liquid paraffin stream

with a flow rate of 17.5 cm/sec (Reproduced with permission, from Sakai S et al. Biotechol. Bioeng.

[28] @ 2004 Wiley Periodicals, Inc.).

Figure 3. Sodium-alginate aqueous solution (194 mPa⋅s) extruded from a needle of 300 μm i.d. and 480

μm o.d. into the ambient liquid paraffin stream. The velocities of the sodium-alginate aqueous solution

and liquid paraffin were 1.2 cm/sec and 23.5 cm/sec, respectively (Reproduced with permission, from

Sakai S et al. Biotechol. Bioeng. [28] @ 2004 Wiley Periodicals, Inc.).