Biomedical Engineering Reference

In-Depth Information

16

14

12

10

8

6

4

2

0

Inedible

Tallow

Yellow

grease

1

Canola

Soybean

Recyle oil

(1)

Diesel

Yellow

grease

2

Recyle oil

(2)

Edible

Tallow

Lard

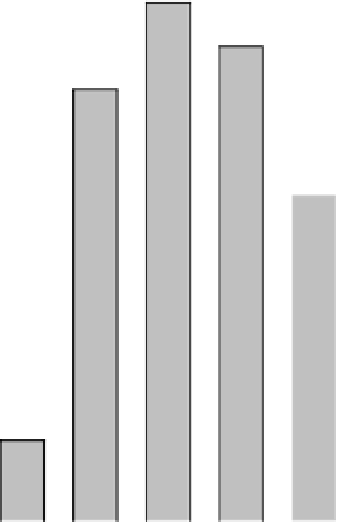

Figure 3. Increase in NOx emissions from CI engines using various B100 fuels.

1.3. Benefits of Biodiesel: Environment

As stated earlier, biodiesel is derived from renewable sources such as vegetable oils,

animal fats, and waste cooking oils. Once produced and used, the byproducts of its

combustion in automobile engines are carbon dioxide and water only. The source of

biodiesel, such as soybeans, will absorb CO

2

during its lifetime through photosynthesis. In

this way, biodiesel is considered carbon neutral. However, when production is considered,

biodiesel is not neutral. Fossil fuels are still required to create the steam, electricity, and

methanol needed for manufacturing, and to fuel the equipment for farming and

transportation and materials. Even with all this fossil fuel input, biodiesel is still an energy

efficient fuel. From one unit of fossil fuel energy used to produce the biodiesel, 3.2 units of

energy are created as biodiesel fuel [4]. It is also estimated that biodiesel still has 41% less

carbon dioxide emissions than petroleum based diesel [2]. Biodiesel also reduces other

emissions such as particulate matter, hydrocarbons, and carbon monoxide. This is due to

the 11% oxygen by weight content that allows for more complete combustion. [4]

Furthermore, biodiesel is a natural substance and therefore is biodegradable if spilled. It is

also comparably better than other popular renewable energies. Soybean based biodiesel has

a 93% energy gain compared to only 25% for corn derived ethanol [5]. An 80000-km

durability test was performed on two engines using diesel and biodiesel (methyl ester of

waste cooking oil) as fuel in order to examine emissions resulting from the use of biodiesel