Biomedical Engineering Reference

In-Depth Information

Membrane processes have wide industrial applications covering many existing and

emerging uses in the chemical, petrochemical environmental, water treatment,

pharmaceutical, medical, food, dairy, beverage, paper, textile and electronic industries (Ho

and Sirkar, 1992). Membrane filtration process is an approach to separate different materials

by semi-permeable membranes. Generally, a membrane process requires two bulk phases to

be physically separated by a third phase or a membrane phase. The membrane is an interphase

between the two bulk phases. The membrane phase may be any or a combination of the

following: nonporous solid, microporous or macroporous solid with a fluid (liquid or gas) in

the pores, a liquid phase with or without a second phase, or a gel (Ho and Sirkar, 1992). In all

membrane processes, the feed is separated into two fractions, i.e. a permeate which passes

through the membrane and a retentate which is rejected by the membrane. Large commercial

scaled uses of membrane processes have displaced conventional separation processes and

more expectation is supposed in the future. Membrane processes have always been an integral

part of biotechnological processes for fermentation, clarification, purification and

concentration. Over the last 30 years, the followings are the widely employed membrane

processes : reverse osmosis (RO), ultrafiltration (UF), microfiltration (MF), nanofiltration

(NF), dialysis (DA), electrodialysis (ED), gas permeation (GP), pervaporation (PV) and liquid

membrane. They are used to produce potable water from sea, to clean industrial effluent and

recover valuable constituents, to concentrate, purify or fractionate temperature-sensitive

solutions (food and drug industry, biotechnology), to remove urea and other toxins from the

blood stream in an artificial kidney, to release certain drugs at a predetermined rate

(controlled release), and so on (Madaeni, 1999).

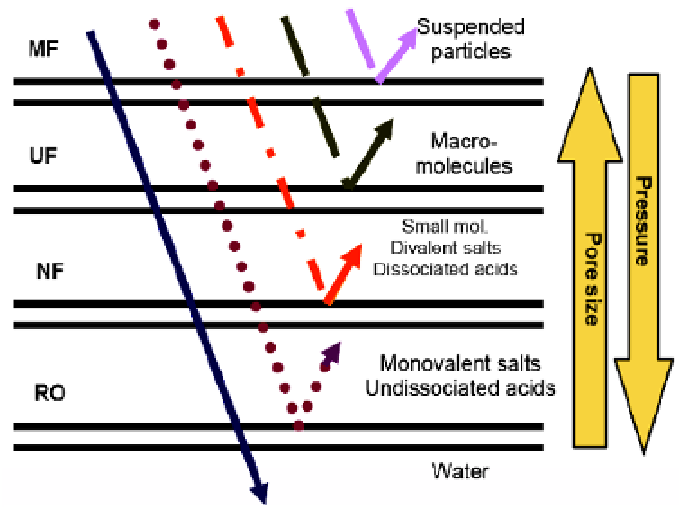

In the case of food industry, pressure-driven membrane processes including

microfiltration, ultrafiltration, reverse osmosis and nanofiltration have been adopted for both

promotion of product and treatment of wastes. Pressure plays a role as driven force.

Figure 1. Classification of pressure- driven membrane processes.

Figure 1 and Table 1 summarized the characteristics of pressure-driven membrane processes.