Environmental Engineering Reference

In-Depth Information

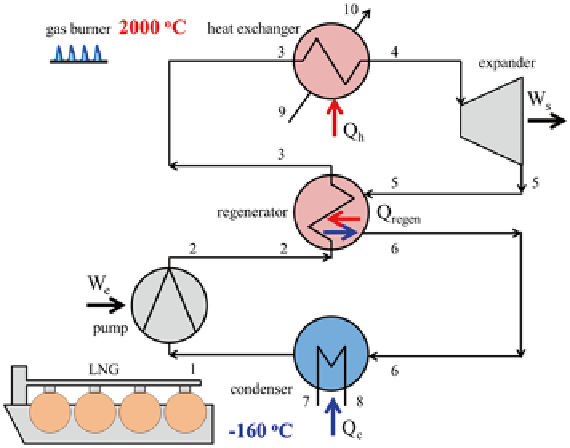

Fig. 5.7

Carbon dioxide energy system for recovering the cryogenic exergy from liquefied natural

gas (LNG) transport vessels with a transcritical carbon dioxide cycle with regeneration. The cycle

operating conditions are similar to those shown in Fig.

5.6

. However, the hot gas exiting from

the expander is used to pre-heat the compressed liquid so that heating requirements for the heat

exchanger are reduced

must be combusted to generate the high temperature required in the heat exchanger

and some amount of electricity must be supplied to the pump for compressing the

liquid CO

2

. Nevertheless, the overall efficiency of the cycle in Fig.

5.6

is close to

46 % and the efficiency can be improved further by using a technique such as regen-

eration that is outlined in Fig.

5.7

.

Regeneration usually refers to the collection of heat available in a gas stream for

reuse in the process. In Fig.

5.7

, CO

2

gas exiting from the expander is still very hot

(ca. 250 °C) and so this heat can be used to pre-heat the feed to the heat exchanger.

By using the available heat, the fuel burned in the gas burner can be reduced so

that the efficiency of the process can be increased. Typically by using one or more

regenerators, process efficiency can be improved by 5-10 %. For an optimized case

that uses high and low pressure expanders with regenerators, a compressor and sea

water, efficiencies as high as 59.0 % have been reported for operating conditions at

700 °C (Angelino and Invernizzi

2009

).

5.3.6

Refrigeration

In refrigeration systems, the cold source of the heat pump is used instead of the hot

source. Equation (5.2) can still be used to evaluate the performance of a heat pump

refrigerator. However, heat generated by compression of the vapor must now be