Environmental Engineering Reference

In-Depth Information

80

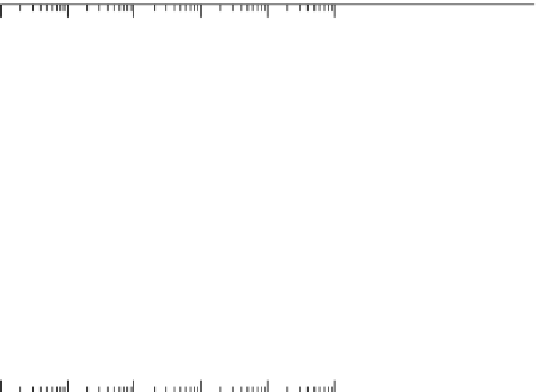

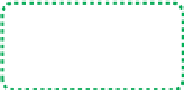

SOFC-GT-ST

1600°C class

60

SOFC-GT

SOFC

(co-gen.

or mono-gen.)

GT-ST combined cycle

“Enefarm”

MCFC

1100°C class

Type -S

PAFC

Steam Turbine

40

PEFC

“Enefarm”

Type -P

20

“Eco-will”

0

10

-1

10

0

10

1

10

2

10

3

10

4

10

5

10

6

10

7

Power Output / kW

Fig. 4.5

Efficiency versus scale for heat engines and fuel cells. (SOFC: solid oxide fuel cell,

PEFC: polymer electrolyte fuel cell, PAFC: phosphoric acid fuel cell, MCFC: molten carbonate

fuel cell, GT: gas turbine and ST: steam turbine)

steam turbine triple combined systems which are expected to achieve an efficiency

of 70 % LHV.

4.3

Type, History, and Mechanism of Fuel Cells

As previously noted, fuel cell reactions proceed through a membrane which trans-

mits ions involved in the combustion reaction of the fuel. The basic electrochemis-

try of the fuel cell can be traced back to Sir William Grove in 1838 who was first to

demonstrate how to generate electricity from the reaction of hydrogen and oxygen

(although prior to this, Sir Humphrey Davy proposed a carbon -air battery in 1802

which is sometimes regarded as the beginning of the fuel cell).

The earliest commercial fuel cell used phosphoric acid as the electrolyte (phos-

phoric acid fuel cell: PAFC). In this fuel cell, the electrolyte diaphragm is soaked

with phosphoric acid, and is operated at approximately 200 °C. Porous carbon mate-

rial supporting platinum as a catalyst is used as the electrodes. Systems are available

for sale with an output of 100 kW ~ 200 kW with an efficiency of ~ 40-42 % (LHV).

However, as will be mentioned below, for equipment of this class a gas engine can

achieve a relatively high power generation efficiency at lower cost. Therefore to

take full advantage of the fuel cell's future potential, we need to further improve the

performance.