Environmental Engineering Reference

In-Depth Information

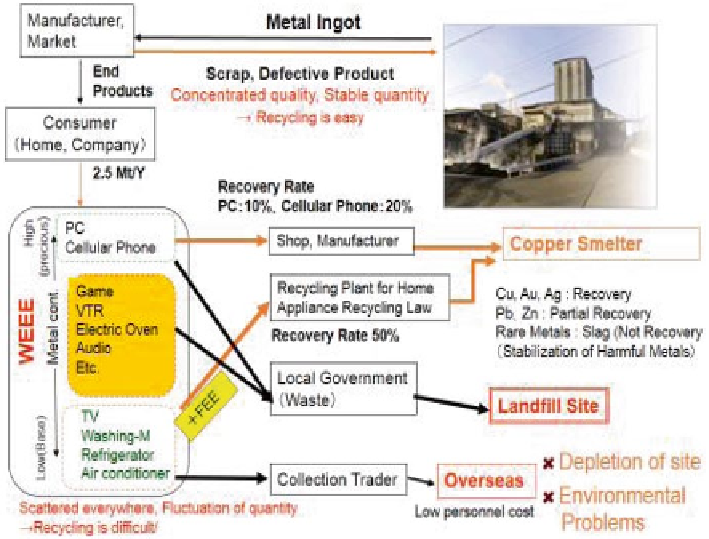

Fig. 13.8

Recycling of non-ferrous metals

through several routes. In the case of WEEE, when copper, gold and silver are col-

lected for recycling, minor metals can also be gathered with them. If minor metals

are separated from WEEE by proper techniques and are accumulated for recovery,

they can be considered as resources. However, recycling of rare earth elements

(REE) from WEEE is still a long way from meeting the demands for them. Why

is the recycling of REE so difficult and what are the essential problems which are

blocking progress in recycling?

There are indeed problems both in the social system and in technologies. The

highest barrier to overcome is to build up a good economical collection system for

WEEE. In the EU, a WEEE directive was established and recycling laws for home

electronics applicants were also established in Japan. However, no strategy to re-

cover minor rare metals was considered in either of these actions. A second bottle-

neck for recovery is the difficulty of recovery technology, especially dismantling

parts containing REE. Most REE-containing parts are small and involve complex

shapes which must be dismantled. For instance the neodymium-iron-boron magnet

has a very strong magnetic force and is sometimes used with steel. A difficulty is

thus separation of REE from other metals like iron. A separation process for dyspro-

sium from neodymium after leaching is not so difficult however.

Precious metals and platinum group metals (PGM) are readily recycled in non-

ferrous metal smelters. Most of recycling resources are put into smelting furnaces

such as copper converters, and they are finally recovered from copper slimes after