Environmental Engineering Reference

In-Depth Information

Table 13.1

Comparison of pyrometallurgical processes for EAF dust treatment in Japan

Process

Furnace

operation

Energy

Product

Raw material

flexibility

De-lead

process

Waelz

Large/complex Coke, car-

bon, oil

Crude ZnO

sinters

Low

Chlorinated

roasting

Rotary Hearth Large/complex Coal, natural

gas

ZnO, iron

Low

-

MF

Small/simple

Coke, oil

Crude ZnO, slag High

-

St. Joseph

Large/complex Electricity

ZnO, sinters

Low

Chlorinated

roasting

DSM

Small/simple

Coal

Crude ZnO

Low

-

)OXHJDV

3XOYHUL]HGFRDO

$LU

%LQGHU

+HDWH[FKDQJHU

,URQRUH

0L[HU

3HOOHWL]HU

'HVXOIXUL]DWLRQ

'U\HU

%DJILOWHU

%XUQHU

5RWDU\+HDUWK)XUQDFH

+%,

+RW'5,

&ROG'5,

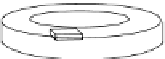

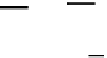

Fig. 13.6

Schematic illustration of Rotary Hearth Furnace process

The Mitsui Furnace (MF) originally developed by Mitsui Mining & Metals, Ltd.

is a unique short blast furnace type as shown in Fig.

13.7

. Briquettes of EAF dust

and cokes are put into the furnace from the top, and hot air is blown from a tuyere

as used in a blast furnace, and ZnO and ZnFe

2

O

4

are reduced to zinc gas by cokes in

the furnace. This process produces crude ZnO and molten slag. Making molten slag

has merit because it is easy to use for construction minerals; however iron cannot

be recycled.

One technical problem of EAF dust is that the pyrometallurgical processes are

not the final stage required to supply metallic zinc but only the middle stage, since

they produce only crude ZnO. One more step such as the ISF (Imperial Smelting

Furnace) process is necessary to refine the crude ZnO into zinc.