Environmental Engineering Reference

In-Depth Information

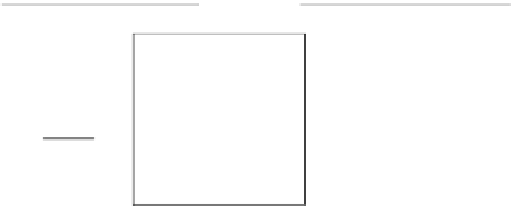

($)'867

3\URPHWDOOXUJLFDO3URFHVV +\GURPHWDOOXUJLFDO3URFHVV

(=,1(;SURFHVV

1+

&OVROXWLRQ

ɾ

:DHO]NLOQSURFHVV

ɾ

5RWDU\KHDUWKSURFHVV

ɾ

0)SURFHVV

ɾ

$XVPHOWSURFHVV

ɾ

'60SURFHVV

ɾ

&RQWRSSURFHVV

ɾ

3ULPXVSURFHVV

ɾ

5DSLGSURFHVV

$FLGOHDFKLQJ

&DXVWLFOHDFKLQJ

2WKHUV

=,1&(;SURFHVV

&OOHDFKLQJ6;(:

6W-RVHSK

SURFHVV

5(&83$&SURFHVV

+

62

OHDFKLQJ

(OHFWURZLQLQJ

&UXGH=Q2

&UXGH=Q2

,6)SURFHVV

3ULPDU\

(OHFWURZLQLQJ

+LJKJUDGH=Q2

+LJKJUDGH=Q

Fig. 13.5

Schematic presentation of EAF dust treatment

dust in the past. There are a number of pyometallurgical processes that have been

operated and such processes are effective in treating large amounts of EAF dust at

one time. However, only crude ZnO can be produced, since the reaction of ZnO in

a pyrometallurgical process is just from (ZnO) in EAF dust (with a concentration of

~ 30 %) → (ZnO) high grade(with a concentration of over 90 %).

During the pyrometallurgical process, ZnO or Zinc ferrite (ZnFe

2

O

4

) is reduced

and metallic zinc vapor is formed but this metallic zinc is oxidized again during

cooling, following thermodynamic principles. Several trials to recover metallic zinc

directly have been made, but no viable process has yet been developed. This is be-

cause cooling of metallic zinc gas to a liquid state without oxidizing is one of the

most difficult of metallurgical techniques.

The pyrometallurgical recycling processes used in Japan are summarized in

Table

13.1

. Each method has a distinguishing feature. The Waelz kiln process is

most popular and the leading technology for treating EAF flue dust and is continu-

ously being optimized for energy input, product and off gas quality.

The rotary hearth furnace process has been developed and operated commer-

cially (McClelland and Metius

2003

). High quality crude zinc oxide is obtained in

the rotary hearth furnace process and the residue is recyclable as an iron source,

although the initial capital investment is relatively high. A schematic process flow is

shown in Fig.

13.6

. Pellets consisting of EAF dust are reduced with pulverized coal,

and zinc is evaporated and also cooled down in the rotary furnace. This furnace is

used to treat blast furnace dust in steelworks in Japan.