Environmental Engineering Reference

In-Depth Information

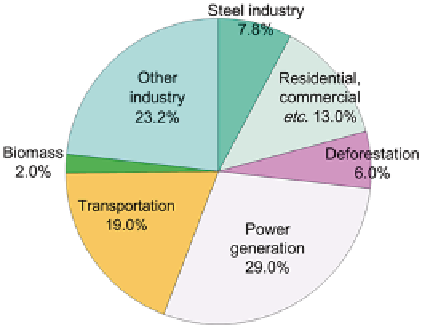

Fig. 12.13

CO

2

emission

from different sectors in the

world (Global emissions in

2011: 33.5 million t)

㻝㻘㻞㻜

㻜

㻝㻘㻜㻜

㻜

㻤㻜㻜

NJW+0

㻢㻜㻜

㻠㻜㻜

㻞㻜㻜

㻝㻥㻡㻜㻝㻥㻡㻡㻝㻥㻢㻜㻝㻥㻢㻡 㻝㻥㻣㻜㻝㻥㻣㻡 㻝㻥㻤㻜㻝㻥㻤㻡 㻝㻥㻥㻜㻝㻥㻥㻡㻞㻜㻜㻜

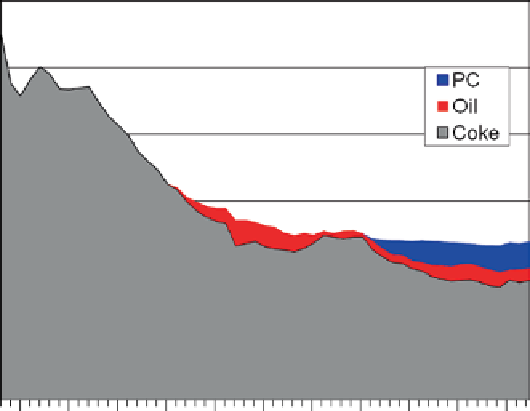

Fig. 12.14

Changes in the reduction reagent rate of the blast furnace ironmaking process

reduced to about 475 kg/ton-steel due to efficient improvements (Fig.

12.14

). How-

ever, such a value is already close to the theoretically ideal condition when one con-

siders the energies necessary for the reduction of iron oxides, and for heating metal

and slag. Therefore a drastic innovation of the process itself is urgently required.

In order to further reduce CO

2

emissions from the iron & steelmaking process, it

is necessary to employ fuel substitution to hydrocarbon gases like natural gas, which

generates less CO

2

, and/or biomass, which is currently classed as a carbon-neutral

fuel. European Union nations started the ULCOS (Ultra-Low CO

2

Steelmaking)

project in 2004, which aims to develop a new iron and steelmaking technology

to reduce CO

2

emissions by more than 50 % from the present value. It completed