Environmental Engineering Reference

In-Depth Information

H

2

H

2

H

2

CH

4

H

2

CH

4

VFAs

CH

4

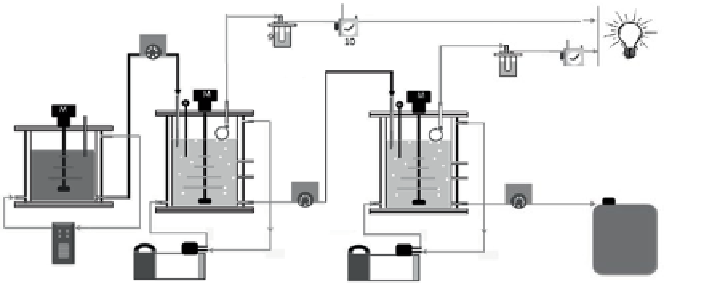

Fig. 8.20

Schematic diagram of experimental apparatus in the two phase process.

1

Feedstock

tank,

2

Feed inlet,

3

Mixer,

4

Recirculation cooler,

5

Sampling pump,

6

fermentation reactor,

7

Hot water recirculation,

8

Thermometer,

9

Gas-water separation chamber,

10

Wet gas metter,

11

Sample port,

12

Effluent pump,

13

Digestion sludge tank

8.4.8

A Case Study at Tohoku University of Bioenergy

Production from Food Waste by a Two Stage Process

As we have seen above, although methane and hydrogen fermentation are well-

developed technologies, co-production of hydrogen and methane in the course of

anaerobic digestion of organic wastes is at only the early stages of development. We

have thus evaluated production of bio-hydrogen and bio-methane and their relation

to the nature of organic waste materials, using a continuous two-stage thermophilic

fermentation process shown in Fig.

8.20

. Three kinds of actual food wastes were

used, specifically, potato, kitchen garbage and okara (Kobayashi et al.

2012

).

The results show that bio-hydrogen potential not only depends on the carbohy-

drate content but also on the hydrolysis pH of the waste, which is affected by the

nature of the waste materials. Production rates for H

2

and CH

4

were 2.1 and 1.2 l/l/d

for potato; 1.7 and 1.5 l/l/d for kitchen garbage; and 0.4 and 1.4 l/l/d for okara in

the continuous processes. The biogas yields were 20-85 ml H

2

/g VS added and

329-364 ml CH

4

/g VS added, respectively. The H

2

yield increased and the CH

4

yield decreased in the order of potato, kitchen garbage and okara.

Potato and kitchen garbage food waste appear to be more promising for sequen-

tial H

2

and CH

4

production in a two stage fermentation process. On the other hand,

okara food waste might be suitable for a cost-effective CH

4

production process,

owing to there being no need for any pre-treatment. These results can thus inform

selection of the most appropriate anaerobic process, and have shown that a two-

phase process can effectively separate H

2

-producing bacteria from methanogenic

archaea in an economically and technically feasible process, to produce hydrogen

and methane simultaneously from waste.

Further research (Chu et al.

2010

) on the two stage system shows that the

activity of the H

2

-producing bacteria can be effectively separated from that of

methanogenic archaea, which makes a process for producing hydrogen and methane