Environmental Engineering Reference

In-Depth Information

H

2

CH

4

H

2

CH

4

CH

4

CH

4

CH

4

+ CO

2

CH

4

+ CO

2

CH

4

+ CO

2

CH

4

+ CO

+

2

H

2

+ CO

2

H

2

+ CO

+

2

VFA

VFA

Sludge

Sludge

C

6

H

12

O

6

+ 2H

2

O

C

6

H

12

O

6

+ 2H

2

O

Sludge

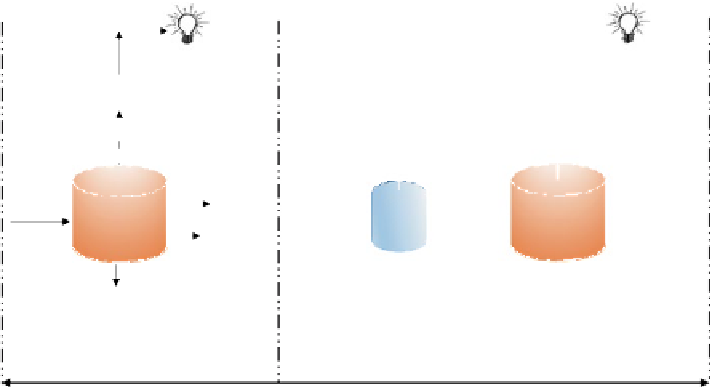

Methane diges

on

process

C

6

H

12

O

6

Methane diges

on

process

Hydrogen

fermenta

on

Organic

ma

er

Organic

ma

er

Wastewater

Wastewater

Organic

ma

er

Wastewater

W

4H

2

+ 2CH

4

+ 4CO

2

1.144KJ + 1.247KJ =

2.391

KJ

3CH

4

+ 3CO

2

1.871

KJ

Single phase technology

Two phase technology

Fig. 8.19

Total energy gained from single phase and two phase processes

in a well operated process, these products are mostly converted to acetic acid and

hydrogen (see Eqs. 8.2, 8.3), which, in turn, are converted to methane gas in a two-

phase anaerobic process (see Eqs. 8.8, 8.9).

Methane fermentation

(

)

C H

O

→+

3CH

3CO

2673

kJ mol

/

(8.7)

6

12

6

4

2

H

2

+ CH

4

fermentation

C H

O

+→++

2H O

4H

2CO

2CH COOH

6

12

6

2

2

2

3

2CH COOH

→+

2CH 2CO

(8.8)

3

4

2

(

)

C H

O

+→++

2H O

4H

2CH

4CO

2926kJ / mol

(8.9)

6

12

6

2

2

4

2

Separating the acidogenic and methanogenic steps in the anaerobic digestion

process, provides enhanced stability to the different groups of microorganisms

and better process control. However, despite their higher loading rates, improved

process stability and flexibility, there are few commercial two-stage anaero-

bic digestion units. The added complexity and expense of building and operat-

ing commercial two-stage systems have so far counteracted the yield and rate

enhancements. The theoretically higher biogas yields have also been questioned

since the acidogenic phase separation prevents the hydrogen to methane pathway

(Reith et al.

2003

).