Environmental Engineering Reference

In-Depth Information

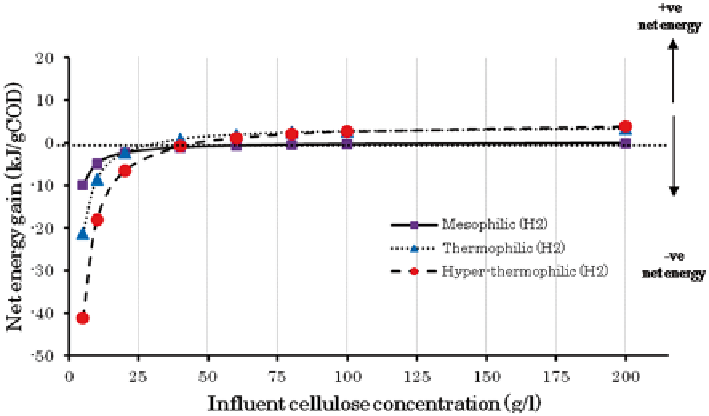

Fig. 8.8

Net energy gain at different fermentation temperatures for different influent cellulose

concentrations

As can be seen from Fig.

8.8

, even though the higher fermentation temperatures

(thermophilic and hyper-thermophilic) are viewed as favorable for high yield and

stability of hydrogen production, the net energy gain was significantly negative

relative to mesophilic conditions at low concentrations of cellulose ≤ 20 g/l. These

results are consistent with those reported for thermophilic temperatures (55 ºC),

where the same net energy gain was obtained (− 20.7 kJ/g COD) using cellulose-

containing wastewater and − 22.6 kJ/g COD using starch wastewater (Karnayakage

et al.

2012

). If cellulose concentrations can be increased to ≥ 40 g/l however, the

thermophilic fermentation is expected to have a better economic performance for

bio-H

2

production. This is especially the case when using feedstocks which are

pretreated to break down cellulosic biomass by chemical, mechanical or thermal

disintegration which overcomes the rate limiting step of biological hydrolysis,

improving the anaerobic fermentation process and biogas yield.

8.4

Methane Fermentation

8.4.1

Background

Methane fermentation is a well-established technology used for treating organic

residues almost regardless of their composition. It is carried out by heterogeneous

microbial populations involving multiple biological and substrate interactions with

end production of methane (55-75 vol %), CO

2

(25-45 vol %) and fermentation