Biomedical Engineering Reference

In-Depth Information

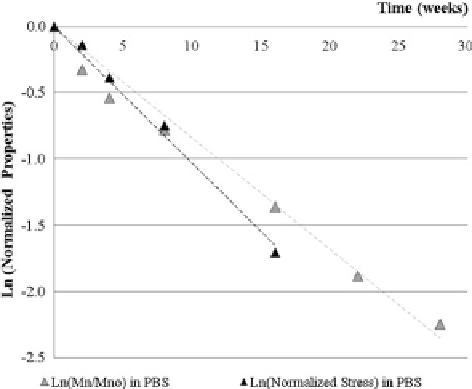

Fig. 9

Normalized strength

and normalized molecular

weight evolution for different

degradation time of

PLA-PCL fibers of 400 µm

under PBS

on the initial material mechanical properties. However, the lack of design tools to

predict long term behavior has limited the application of biodegradable materials.

A constitutive model for a mechanical analysis is a relationship between the re-

sponse of a body (for example, strain state) and the stress state due to the forces

acting on the body, which can include the environmental effects. A wide vari-

ety of material behaviors are described with a few different classes of constitutive

equations. Mechanical properties of biodegradable plastics are commonly assessed

within the scope of linearized elasticity, despite the clear evidence that they can un-

dergo large strains before breaking. Due to the nonlinear nature of the stress

vs

,

strain plot, the classical linear elastic model is clearly not valid for large strains

simulation. Other plasticity or hyperelastic models are required to model those situ-

ations. Hence, given the nature of biodegradable polymers, classical models such as

the Neo-Hookean and Mooney-Rivlin models, for incompressible hyperelastic ma-

terials, may be used to predict mechanical behavior until rupture of non-degraded

PLA [

13

,

26

]. A single-order, isotropic Ogden material hyperelastic model was also

used [

23

] to simulate the mechanical behavior evolution during degradation of a

polyester-urethane scaffold.

These models are useful to model the toughness of materials with this type of

mechanical behavior. For these materials, the work assumption implies the existence

of a scalar field, the stored energy function

W

, which is a function of the deformation

gradient

F

. The stored energy function,

W

, can also be represented as a function of

the right Cauchy-Green deformation tensor invariants. In general, the strain energy

Ta b l e 1

Degradation rate of PLA-PCL under PBS, determined by measuring strength and molec-

ular weight evolution for different degradation time

Ln

(σ/σ

o

)

=−

u

s

t

R

Ln

(M

n

/M

o

)

=−

u

m

t

R

u

0.103

0.996

0.0841

0.989

Search WWH ::

Custom Search