Environmental Engineering Reference

In-Depth Information

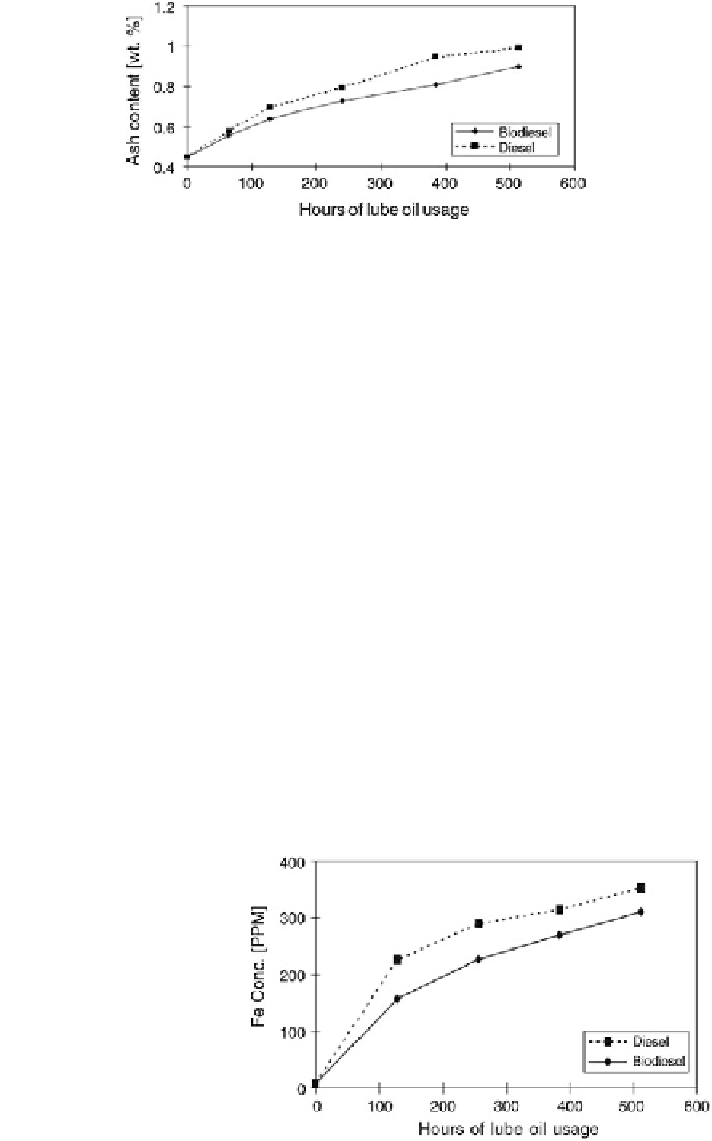

Fig. 6 Ash content of the lubricating oil samples from diesel- and biodiesel (B20)-fueled engines

(Agarwal

2003

)

diesel-fueled CI engine is shown in Fig.

6

(Agarwal

2003

). Ash content for B20-

fueled engine was lower than diesel-fueled engine, which shows that biodiesel-

fueled engine produces lower wear debris (Agarwal

2003

).

4.6 Atomic Absorption Spectroscopy

Agarwal et al. (

2003b

) and Agarwal (

1999

) carried out wear metal analysis using

atomic absorption spectroscopy (AAS) of the lubricating oil samples drawn from

biodiesel (B20)- and diesel-fueled engines (Figs.

7

and

8

). The biodiesel-fueled

engine produced lesser wear of engine moving parts as seen from lesser metallic

debris, originating from different interfaces of moving parts and getting accumu-

lated in the lubricating oil (Agarwal et al.

2003a

,

b

).

Based on these exhaustive engine and tribological investigations of the lubri-

cating oil, Agarwal (

2005

) concluded that biodiesel can overcome most of the

operational durability concerns existing with vegetable oils such as fuel

filter

plugging, injector coking, carbon deposits in the engine combustion chamber,

in addition to issues such as ring sticking and contamination of lubricating oils.

Fig. 7 Iron concentration as

a function of lube oil usage in

the lubricating oil samples

from diesel- and biodiesel

(B20)-fueled engines

(Agarwal

2003

)

Search WWH ::

Custom Search