Environmental Engineering Reference

In-Depth Information

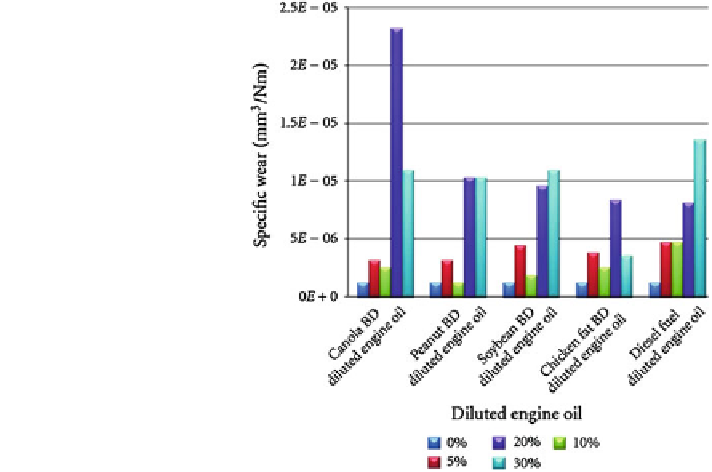

Fig. 5 Speci

c wear for

mixtures of four biodiesels

and mineral diesel diluting the

lubricating oil (Shanta et al.

2011

)

was in 5, 10, 20, and 30 % volume ratios. For all tested biodiesels, contaminated

mixtures, the average friction force did not vary signi

cantly as compared to that

for mineral diesel contaminated and that for pure oil (Fig.

5

). As per results for the

0

10 % dilution range, the observed wear for each biodiesel mixture was not

substantially different and even slightly lower than that for same percentage of

mineral diesel-fuel contamination. For the four tested biodiesel mixtures, the

measured wear seemed to peak for around 20 % blends. However, the mineral

diesel in oil mixture showed a monotonic increase of wear in the tested 0

-

30 %

-

contamination interval (Shanta et al.

2011

).

Arumugam and Sriram (

2012

) addressed the issue of friction and wear charac-

teristics of diesel engine cylinder liner

piston ring combinations under different

lubricating conditions using a pin-on-disk wear tribometer. They reported that the

rapeseed oil-based bio-lubricants and biodiesel-contaminated synthetic lubricants

exhibited better performance in terms of wear, friction, and frictional force under

similar operating conditions.

-

4.3 Wear Metal Measurement Through Lubricating Oil

Analysis

The quantitative evaluation of wear particles present in oil gives the magnitude of

engine component deterioration, while qualitative analysis indicates its origin.

Sinha and Agarwal (

2010

) analyzed wear metal in lubricating oil samples and

Search WWH ::

Custom Search