Environmental Engineering Reference

In-Depth Information

in suspension in the lubrication oil as minute metal debris. Therefore, sources of

these elements and the engine condition (engine health) can be predicted and

monitored by analyzing the concentration and variations in the metallic wear debris

in the lubricating oil after a

fixed operating interval.

Fazal et al. (

2011

) summarized comparison of wear of biodiesel- and mineral

diesel-fueled engines in a review article. They concluded that either lower or similar

wear takes place in biodiesel/biodiesel blend-fueled engines in comparison with

mineral diesel-fueled engines, for both static engine tests as well as

field trials (Fazal

et al.

2011

). Agarwal and Das (

2001

) also concluded from a 512-h-long endurance

test, which they conducted on a single-cylinder engine using B20 of linseed bio-

diesel, that biodiesel does not have any signi

cant adverse impact on wear of various

vital moving components of the engine. Verhaeven et al. (

2005

) reported that there

was no signi

cant difference in the wear of the fuel injectors and fuel injection

equipment, even after 100,000 km

field trial with alternate fuels namely rapeseed oil

methyl ester (RME) and used vegetable oil methyl ester (UVOME). Sinha and

Agarwal (

2010

) reported physical measurements of various vital engine components

and showed lower wear for B20-fueled engine in comparison with mineral diesel-

fueled engine except for big end bearing, which showed slightly higher wear for

B20-fueled compression ignition direct injection (CIDI) engine.

Ç

etinkaya et al.

(

2005

) observed almost identical level of carbon deposits on the fuel injectors of the

two vehicles fueled with used cooking oil-based biodiesel and mineral diesel in a

7,500-km

field test in winter conditions. Pehan et al. (

2009

) reported similar carbon

deposits in the combustion chambers of biodiesel- and diesel-fueled engines.

Agarwal and Dhar (

2010

,

2012

) reported higher carbon deposits on the piston of

straight vegetable oil- (Karanja oil) and blend-fueled engine in comparison with

mineral diesel-fueled engine in a long-term endurance test.

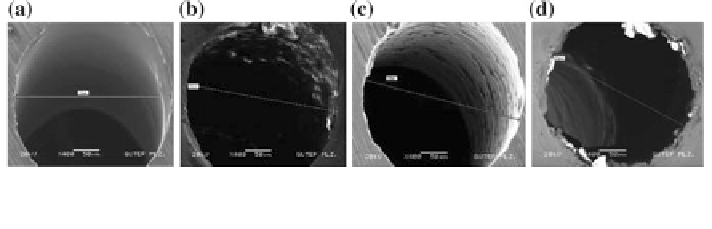

Celik and Aydin (

2011

) investigated the effects of biodiesel on the fuel injector

and fuel injection pump piston used in a diesel engine by using two identical

engines with the same technical speci

cations, but operated on petroleum diesel and

100 % (B100) biodiesel for 200 h. SEM analyses showed signi

cant structural

changes on the surfaces of the injector nozzle used for B100. Less shrinkage was

observed in the engine injector nozzle using petroleum diesel compared to the one

using biodiesel (Fig.

1

) (Celik and Aydin

2011

).

Fig. 1 SEM analyses of injector nozzles a before and b after diesel; c before and d after biodiesel

usage (Celik and Aydin

2011

)

Search WWH ::

Custom Search